When I first started out as a machinist, tap drills totally confused me. I knew I needed the right sized drill bit to make a properly sized hole before tapping it with threads, but figuring out which one to use seemed like a mystery. The shop veterans would grab these simple charts that matched up drill and tap sizes, and suddenly they’d know exactly which bit to grab. Well let me tell you, those tap drill charts became my best friend real fast! I’ve got a whole collection of them printed out and tucked by my drill press now.

Having the right tap drill chart on hand saves me so much time and headaches. No more guessing or messing up the thread sizes. In this article, I want to walk through how to read these charts, which drill bit you need for the common tap sizes, and the best places to find and download a PDF chart for free. Trust me, if you start using a tap drill chart, you’ll be tapping threads like a pro in no time. These handy little charts are one of the best tools in my shop!

Table of Contents

What Is A Tap Drill Size?

![41+ Free Printable Tap Drill Size Charts [PDF] 1 Tap Drill Chart](https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2-1024x576.jpg 1024w, https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2-300x169.jpg 300w, https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2-768x432.jpg 768w, https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2-1536x864.jpg 1536w, https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2-1200x675.jpg 1200w, https://www.typecalendar.com/wp-content/uploads/2023/03/Tap-Drill-Chart-2.jpg 1920w)

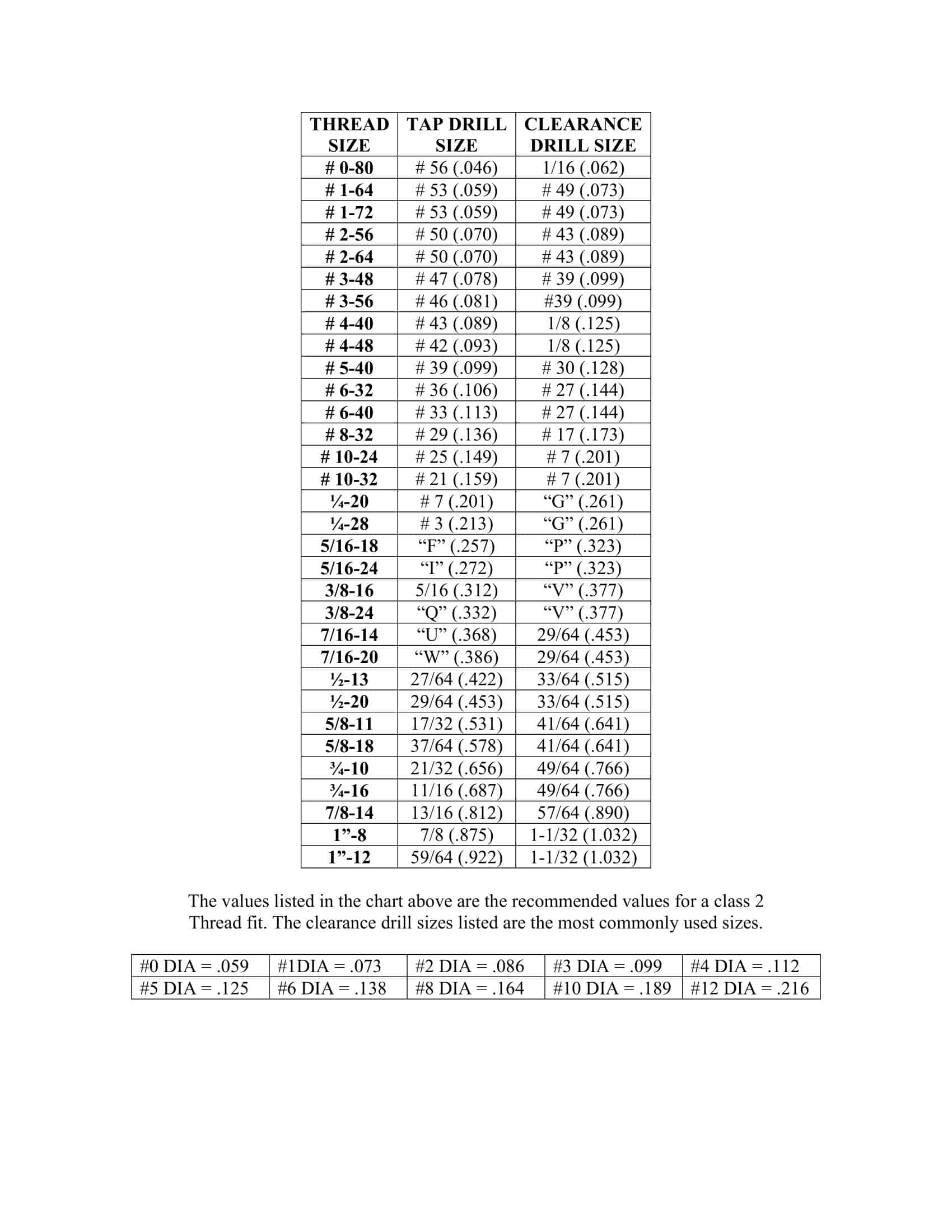

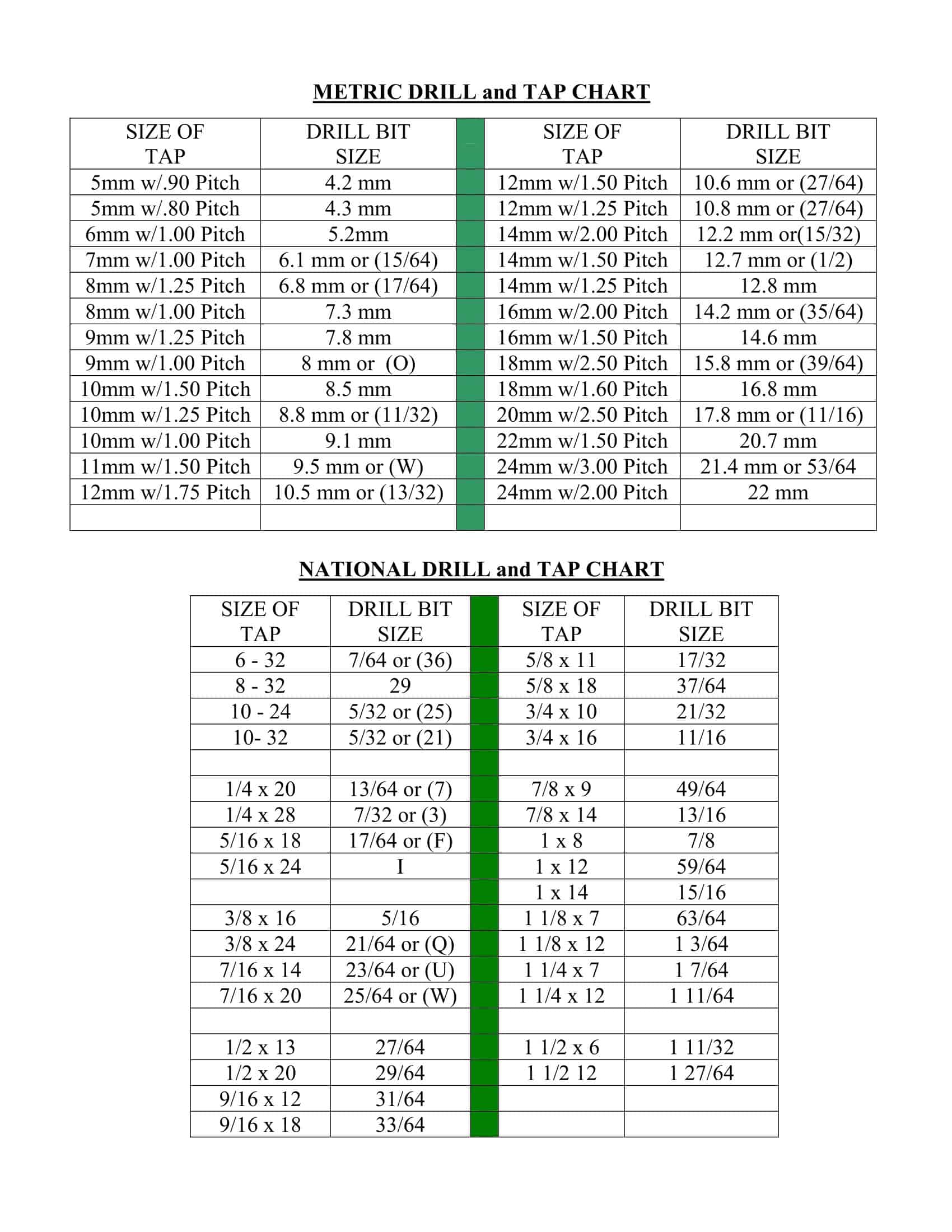

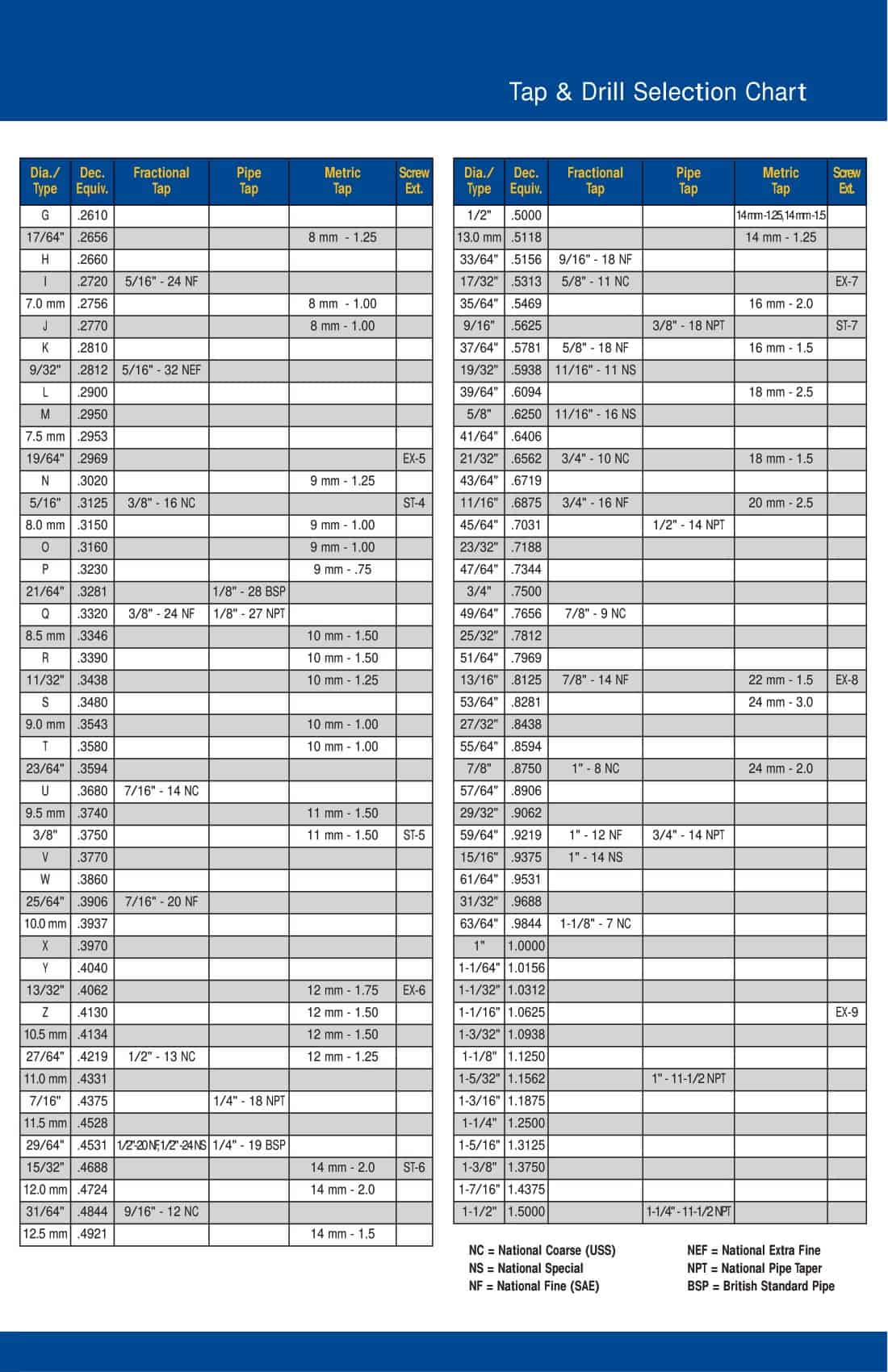

In precision machining, identifying the appropriate tap drill size is indispensable for creating robust and accurate internal threads. This process entails pre-drilling a hole of a specific diameter, determined by the tap size and the desired thread pitch, serving as a precursor to the application of a threading tap.

The correct tap drill size ensures optimal thread engagement, preventing scenarios where an overly large hole leads to weak threads with insufficient hold, or a too-small hole results in undue stress on the tap, potentially causing it to break. Professionals rely on standardized charts to pinpoint the exact drill bit required, taking into account factors such as material hardness and thread specifications, thereby safeguarding the integrity of both the components and the tools used in their fabrication.

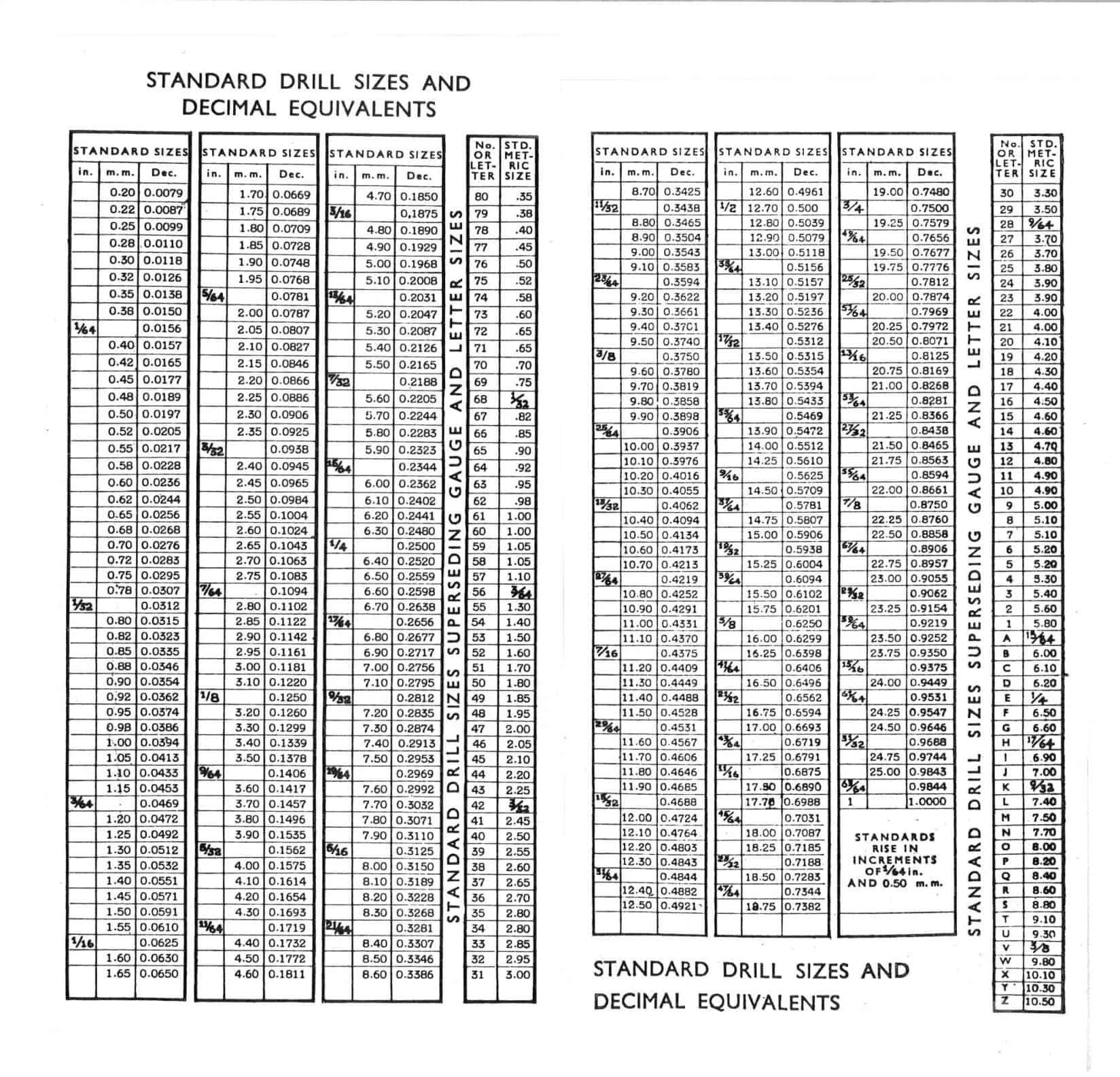

How to Convert Drill Bit Sizes

To accurately convert drill bit sizes, you’ll first need to get your hands on a drill bit conversion chart. This tool can often be found online and is essential for matching bit diameters to their respective designations in both metric (millimeters) and imperial (inches) measurements. In any machining task, choosing the right drill bit is half the battle. Whether you’re preparing for fastening, construction, or assembly, the diameter of the hole is crucial. Although there are numerous techniques for bore creation, employing the correct drill bit remains the primary and most efficient method.

Every standard drill bit size aligns with particular applications and materials. Typically, the diameter of the bit will be slightly larger than the minor diameter (the narrowest part) of the intended screw or bolt, yet smaller than its major diameter (the widest part). When selecting a drill bit, it’s not just about diameter alone. You also need to factor in the type of threads on your fastener, whether they’re fine or coarse, as this determines the suitable thread pitch. By considering the thread spacing, you ensure the hole’s compatibility with the intended screw or bolt. The depth of threading produced by a tap can vary, ranging from 50% to 100%, contingent on the hole’s diameter, further emphasizing the importance of the drill bit size selection process.

How to Use the Drill Chart?

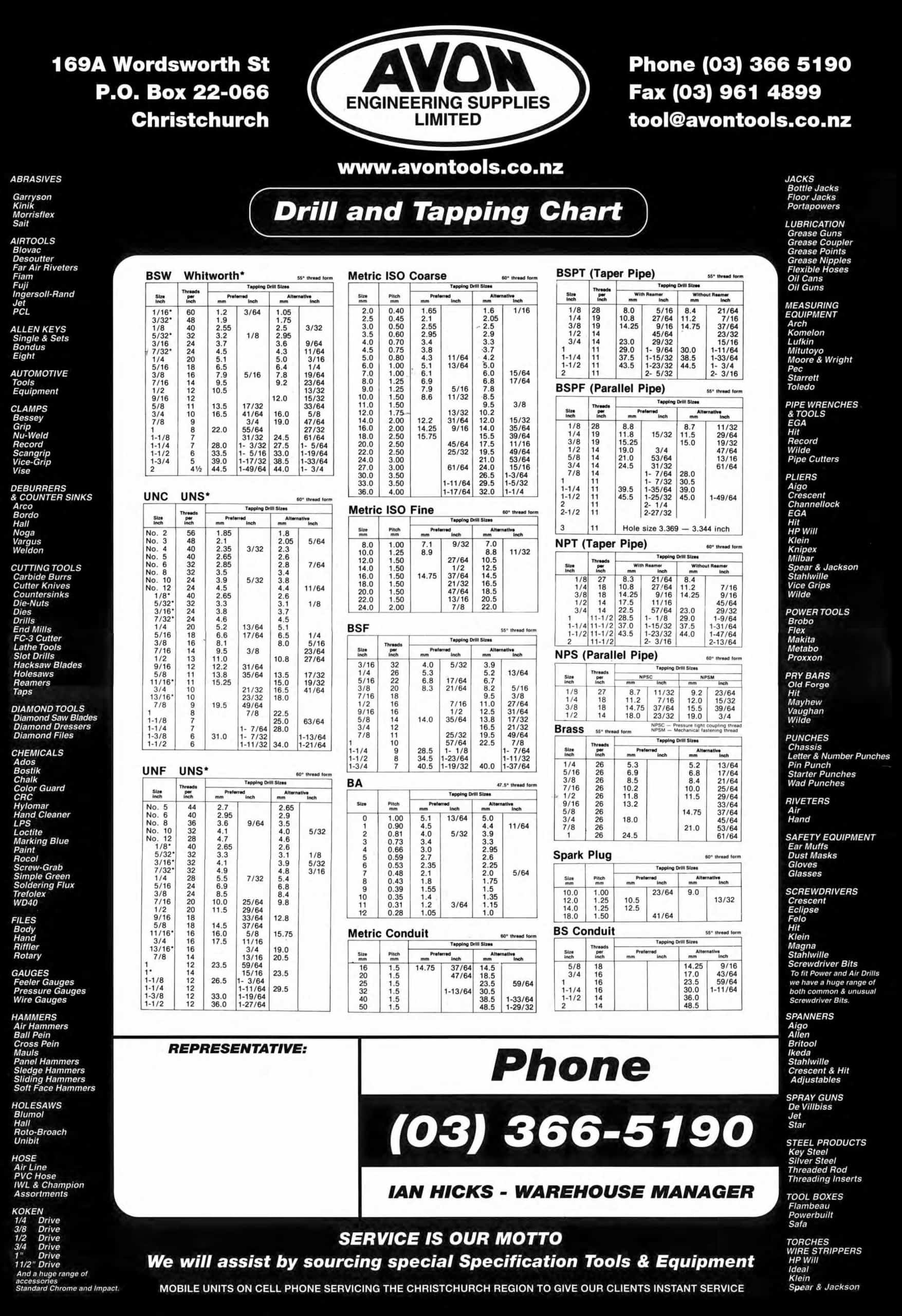

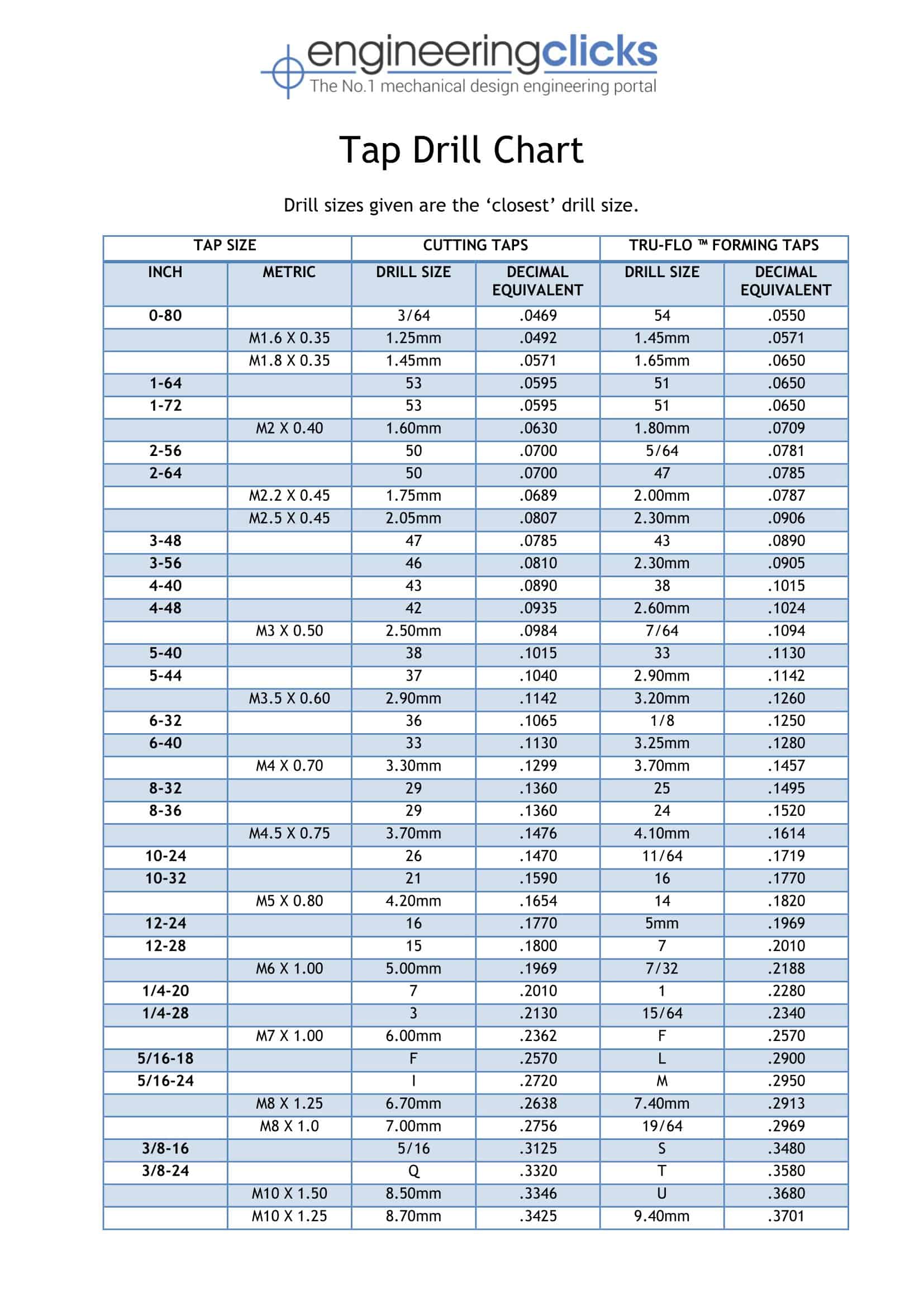

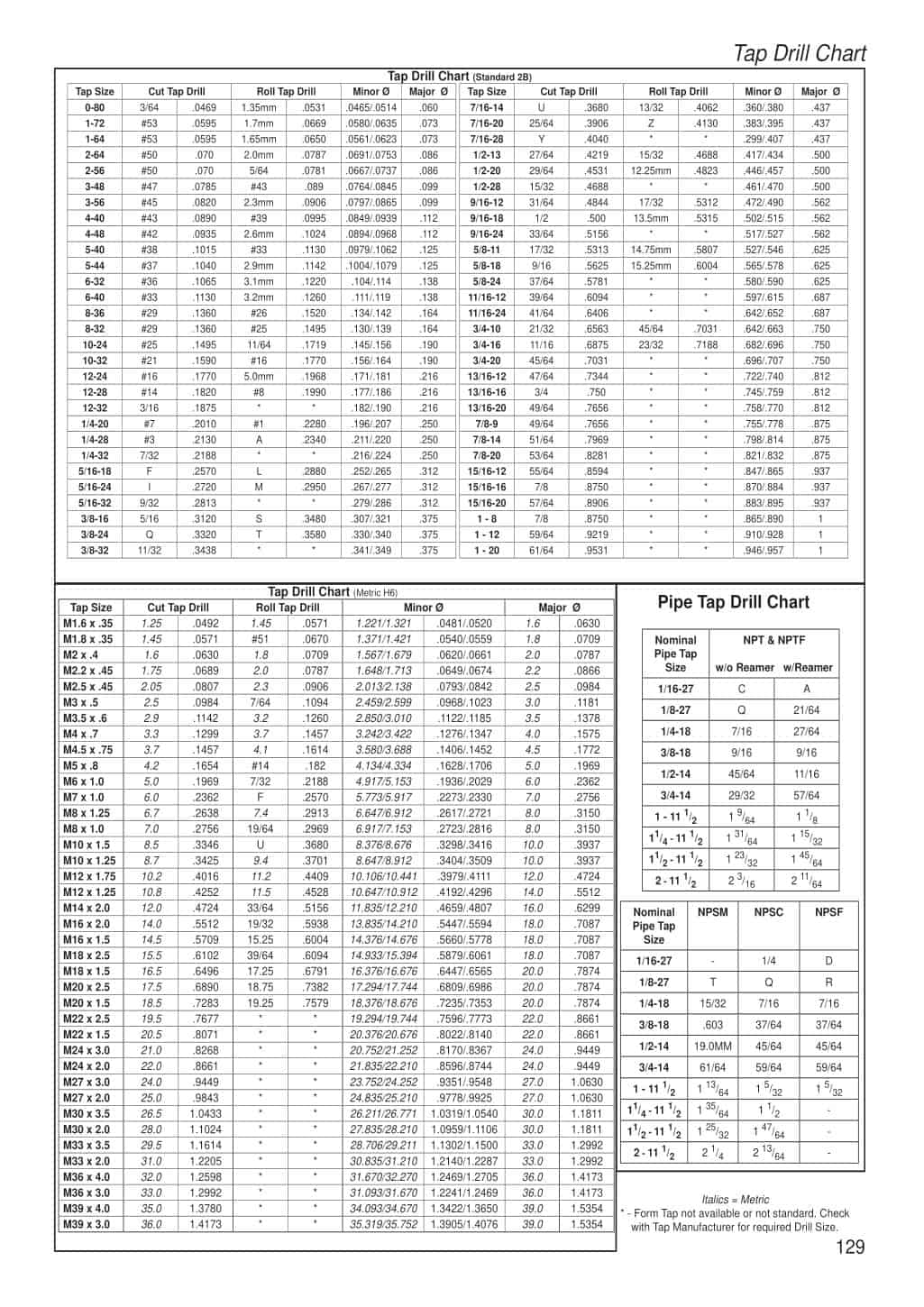

Craftsmen, builders, and manufacturing experts often turn to drill and tap charts as their roadmap for pairing the perfect drill and tap sizes, the combo that paves the way for seamless, screw-fit guides. These charts are the unsung heroes in workshops, factories, and even home garages, ensuring every predrilled component is primed and ready for its matching piece. The magic begins with sizing up the drill bit on the chart, pinpointing the one that’s destined to bore the perfect hole.

Once that’s sorted, it’s go-time: drill that hole, secure the tap, and let it dance its way in, carving out precise guides as it twists and turns. This isn’t just about making room for screws; it’s about precision—a snug, almost hand-in-glove fit for the screw threads. And yeah, these charts are masters of versatility, catering to both woodwork wonders and metallic masterpieces.

Now, here’s the kicker: you’ll stumble upon something called Imperial Charts. These bad boys are your go-to when you’re dealing with diameters in good ol’ inches, not millimeters. They serve up the same wisdom but in a language that’s gold when you’re eyeballing inch-sized drill bits. But don’t get too cozy yet; depth’s a slippery game, and it shifts across charts. Metal mavens need to know their target depth like the back of their hand, sticking to one chart that speaks their project’s language.

Ready for a walkthrough? Let’s breathe new life into a thread-worn hole. Kick things off with a re-drill, guided by the wisdom of your tap and drill chart. Drill in hand, it’s time to make some noise. With the hole set, crown your tap with a holder, cranking it tight. Dive that tap tip-first into the hole, keeping it dead straight. Push and twist it down—feel it biting into the metal or wood, carving out new threads? That’s gold. After a couple of full-hearted turns, ease up—twist the tap back half or three-quarter of a turn. You might need to go easy with three turns at first, not two. It’s all about breaking the chip, keeping things clean.

Playing with dies? They’re cut from the same cloth but play a different game. Dies are all about the outside thread, hugging the contours of a rod, not nestling inside a hole. The golden rule? Size matters. Your die has to mirror your rod. Dreaming of a 3/8” thread? Your die better match up. That’s the art and science of it, right there.

How Do You Read A Drill Tap Size Chart?

In the hands of a skilled professional, a tap drill chart transforms from a simple table into a critical guide that ensures every screw fits perfectly, every joint holds steadfast, and every machine operates smoothly. It’s more than lines and numbers—it’s the language of precision engineering.

Now, picture a standard tap drill chart. It’s usually a straightforward table, but it holds crucial information. You’ve got your thread count, right there telling you about the ‘fineness’ of your threads per inch. You see, that’s crucial when you’re deciding on the strength and compatibility of the screws and holes in question. Then there’s the drill size, which, as you know, has to match the inner diameter of the threaded hole you’re aiming for. And let’s not forget about the material type – because that’s your cue for the kind of drill bit you’ll need. Whether you’re drilling into softwood, hardwood, aluminum, or steel, this choice can make or break the success of your thread.

Now, about the taps. These are your go-to tools for cutting those internal threads. But not all taps are created equal. You’ve got:

- Taper taps: Think of these as the ‘starters.’ They gently prepare the way for the thread, cutting gradually. They’re perfect for through-holes because they allow for an easy start, with their tapered end leading the charge.

- Bottoming taps: These are the ‘closers’ in the team. When you need threads that run deep and go all the way down, these are your guys. They cut threads flat and make sure you’re covered to the very bottom of blind holes.

- Plug taps: Here’s your everyday player, the reliable ‘middle-ground’ option. They cut threads that don’t go all the way through, nor stay too shallow. They’re about just the right depth—ideal for most standard threading tasks.

- Machine screw taps: These are your specialists, designed for the precision required in smaller, finer threaded holes, typically seen in intricate electronic assemblies.

And here’s the thing: the tap drill chart is your playbook. It tells you, “Hey, for this size of a screw, and this kind of material, here’s the drill size you’ll need.” It’s like having a seasoned coach by your side, guiding you on what move to make next.

So, when you look at your chart, and you’ve got your specs right in front of you, what you’re really doing is ensuring that every component fits flawlessly. You’re preventing the kind of errors that cause weaknesses in structures or malfunctions in machinery. You’re not just making holes; you’re crafting seamless connections that can withstand pressure, time, and use.

Final Words

Being able to accurately read and interpret tap drill charts is a critical skill for any machinist. As we’ve seen, these charts provide the recommended drill sizes to use when tapping holes for various thread sizes and materials. Tap drill charts come in many formats – from basic tables to detailed color-coded graphs – but all serve the same crucial purpose. For the highest quality and most precise results, be sure to reference the latest charts from reputable suppliers.

New improved tap drill charts are always being developed as thread standards evolve and advanced materials emerge. With the proper drill size selected from a high-quality, up-to-date tap drill chart, machinists can efficiently produce threaded holes that meet even the most stringent specifications. Accurate, reliable threads start with understanding how to make the most of this indispensable machining resource – the tap drill chart.

![Free Printable Morse Code Charts [Numbers, Alphabet] 2 Morse Code Chart](https://www.typecalendar.com/wp-content/uploads/2023/09/Morse-Code-Chart-150x150.jpg)

What are the advantages of using a printable tap drill size chart, and how can it benefit individuals engaged in machining or metalworking projects?