A crucial aspect contributing to food spoilage is temperature fluctuations, which significantly impact temperature-sensitive items, such as medical supplies and perishable food products. Industries involved in food handling often rely on temperature log templates as a primary safety measure for monitoring food safety standards.

This vital record guarantees that food is processed and stored under appropriate conditions and optimal temperatures. Moreover, temperature logs can be utilized to track the temperature consistency of different appliances, medical equipment, and transportation vehicles.

Table of Contents

What is a temperature log sheet?

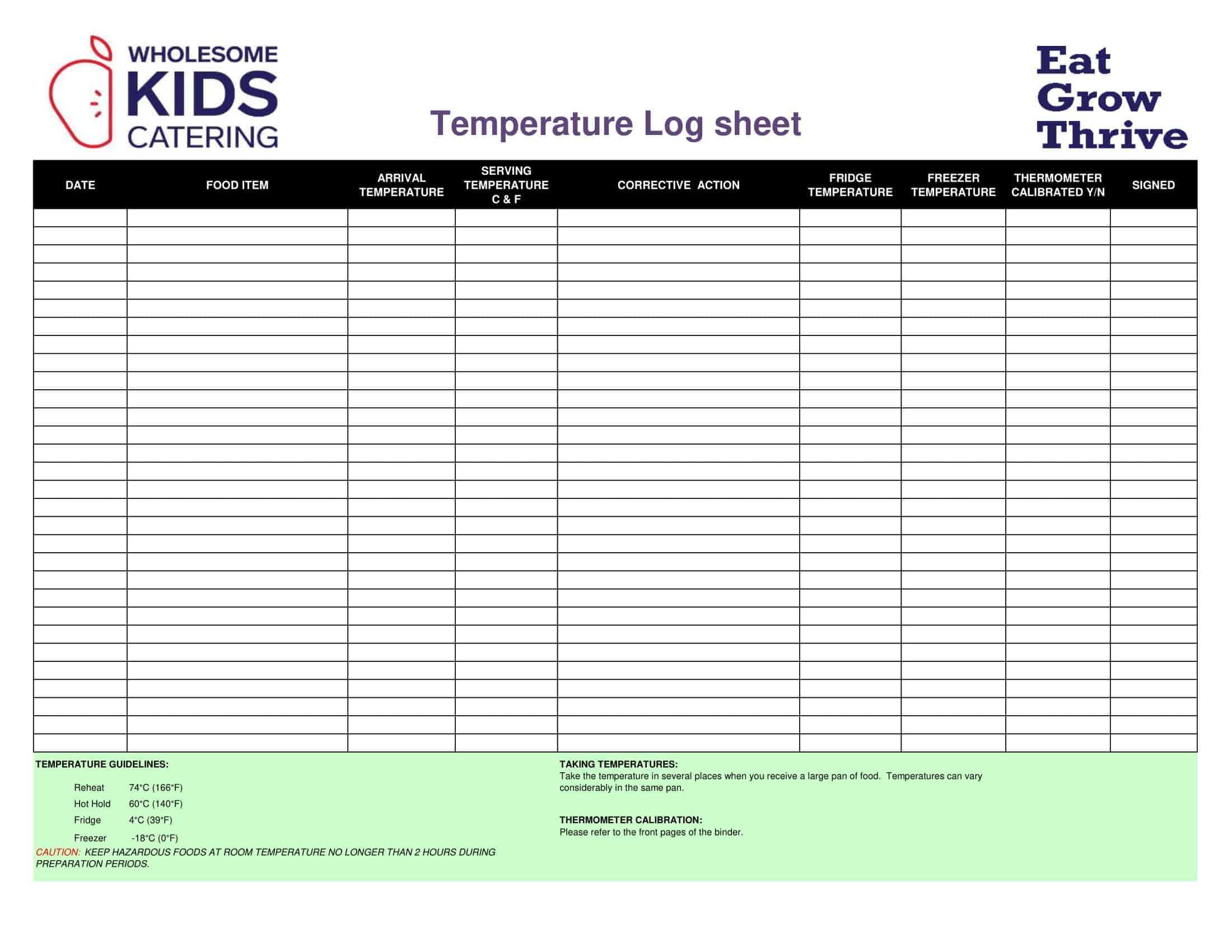

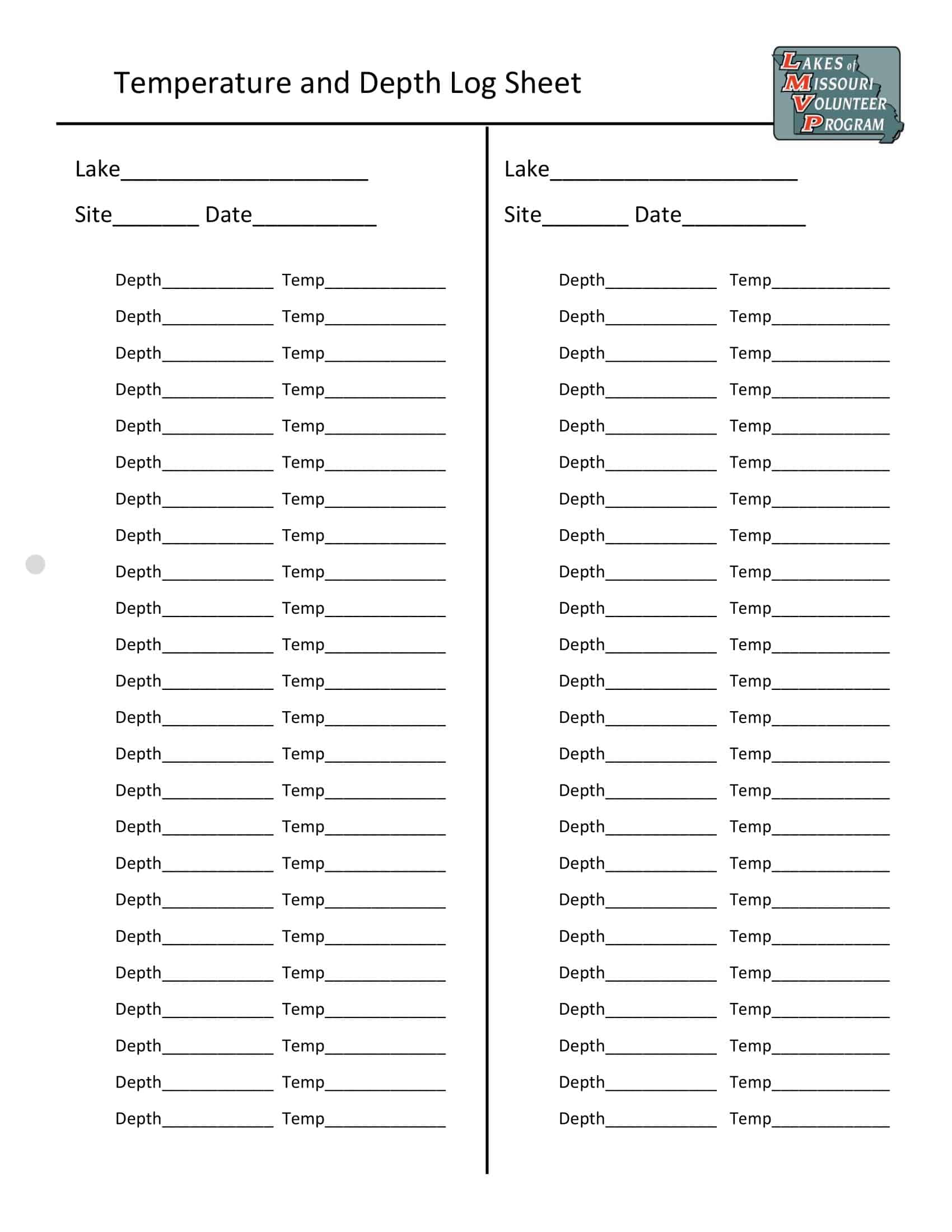

A temperature log sheet is a document used to record and monitor temperature readings at regular intervals for various purposes, such as ensuring the proper storage of perishable items, maintaining the correct functioning of appliances, or monitoring temperature-sensitive equipment.

These sheets are commonly employed in industries like food service, healthcare, and transportation, where maintaining consistent temperature conditions is crucial for product quality, safety, and compliance with regulations. Temperature log sheets help to identify temperature fluctuations, enabling timely corrective actions to prevent spoilage, contamination, or equipment malfunction.

Temperature Log Templates

Temperature log templates are essential tools used across various industries to monitor and document temperature readings in a systematic and organized manner. These templates provide a structured format for recording temperature measurements, ensuring regulatory compliance, quality control, and safety standards. By utilizing temperature log templates, organizations can streamline their temperature monitoring processes, reduce errors, and maintain accurate temperature records for analysis, troubleshooting, and audit purposes.

Temperature log templates offer a valuable solution for organizations across industries that require precise temperature monitoring, compliance with regulations, and maintaining high-quality standards. By utilizing these templates, businesses can streamline their temperature monitoring processes, reduce errors, and ensure accurate and comprehensive temperature records. Ultimately, temperature log templates contribute to enhanced product quality, regulatory compliance, and overall operational efficiency.

Exploring the Different Types of Temperature Log Sheets

Temperature log sheets play a vital role in maintaining safety and quality standards in various industries, ensuring the proper storage and handling of temperature-sensitive items. These records help to monitor temperature fluctuations and prompt necessary actions to prevent spoilage, contamination, or equipment malfunction. In this comprehensive overview, we will delve into the different types of temperature log sheets utilized across multiple sectors.

Food Storage Temperature Log Sheets

Used primarily in the food service and retail industries, these log sheets help maintain the appropriate temperature for perishable items such as meats, dairy products, and frozen goods. They ensure that food items are stored under optimal conditions, minimizing the risk of spoilage and foodborne illnesses.

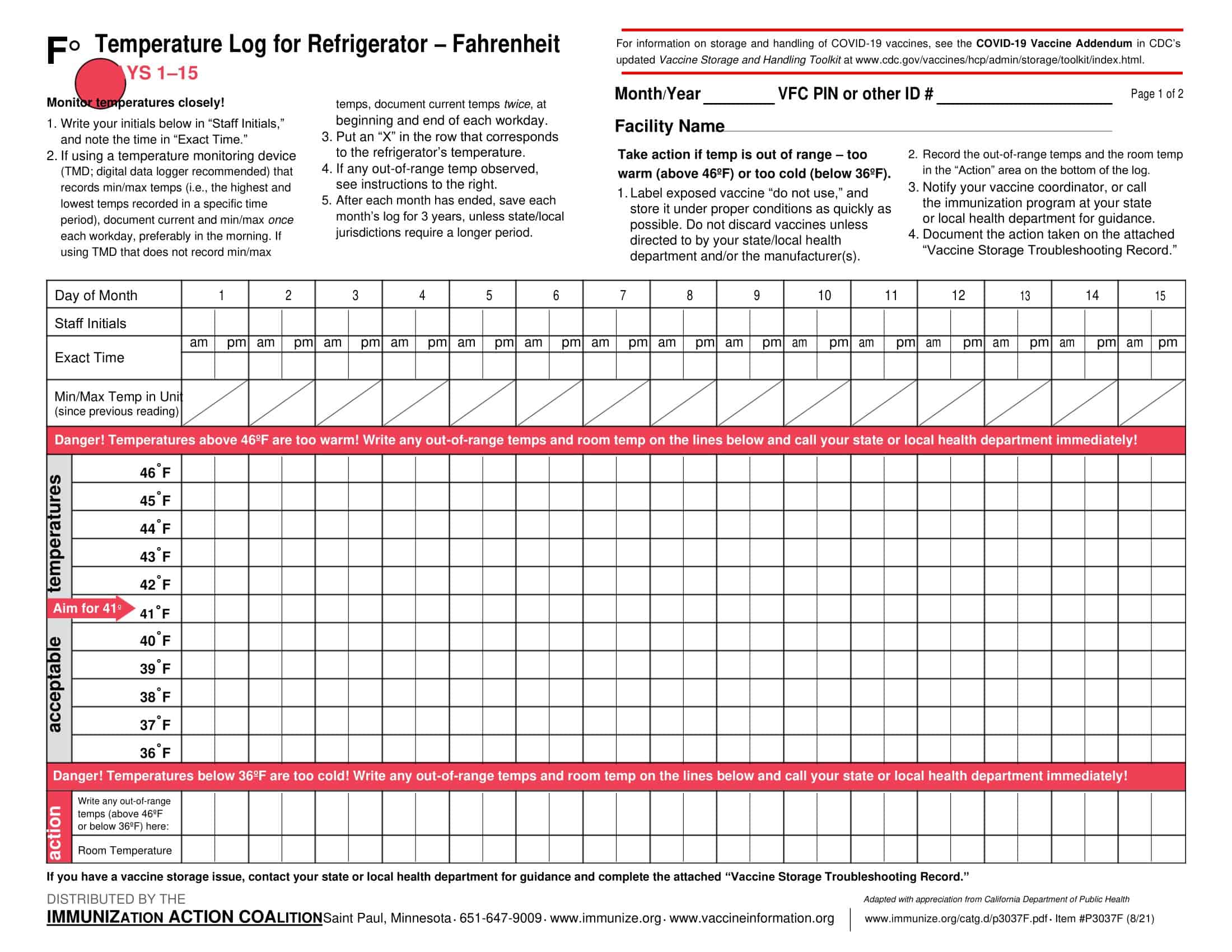

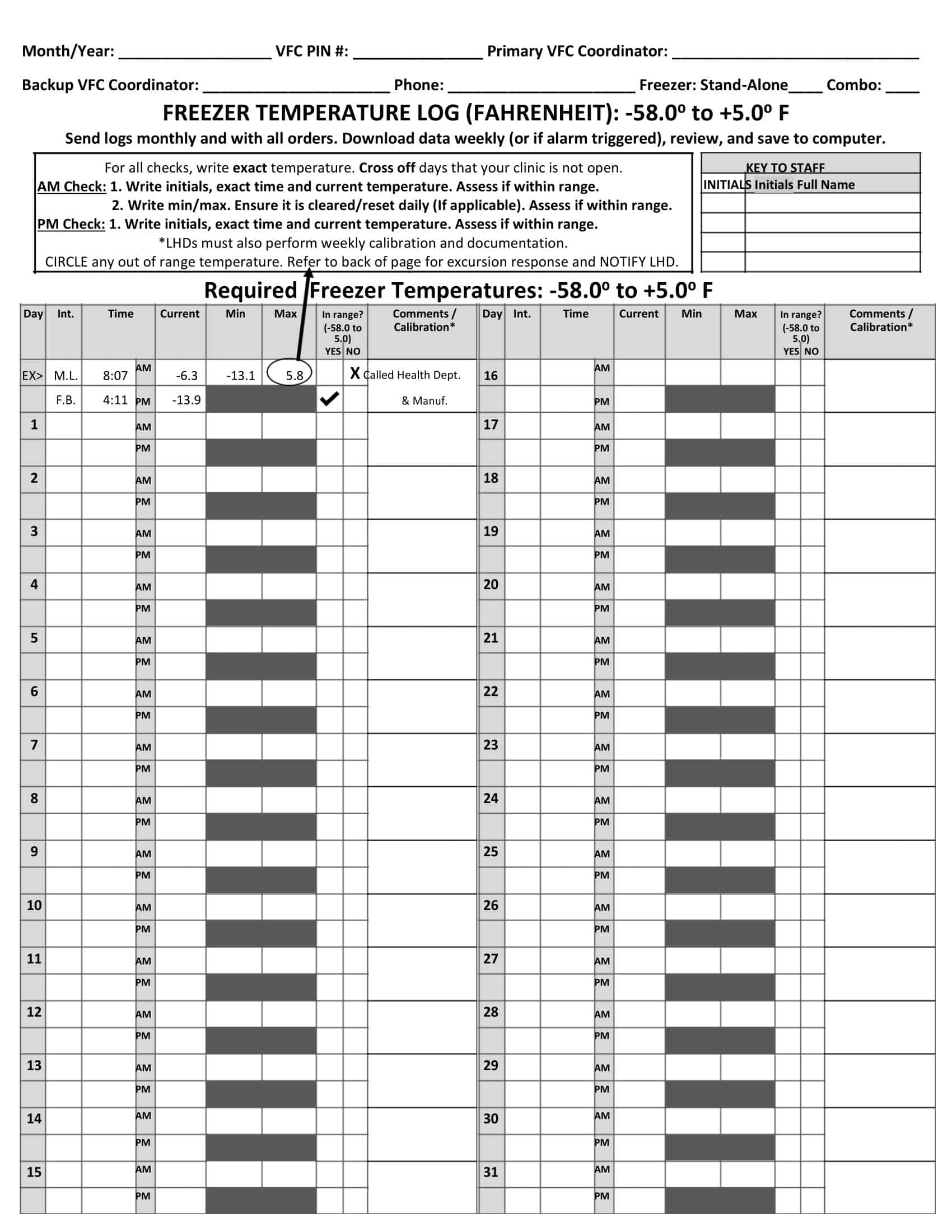

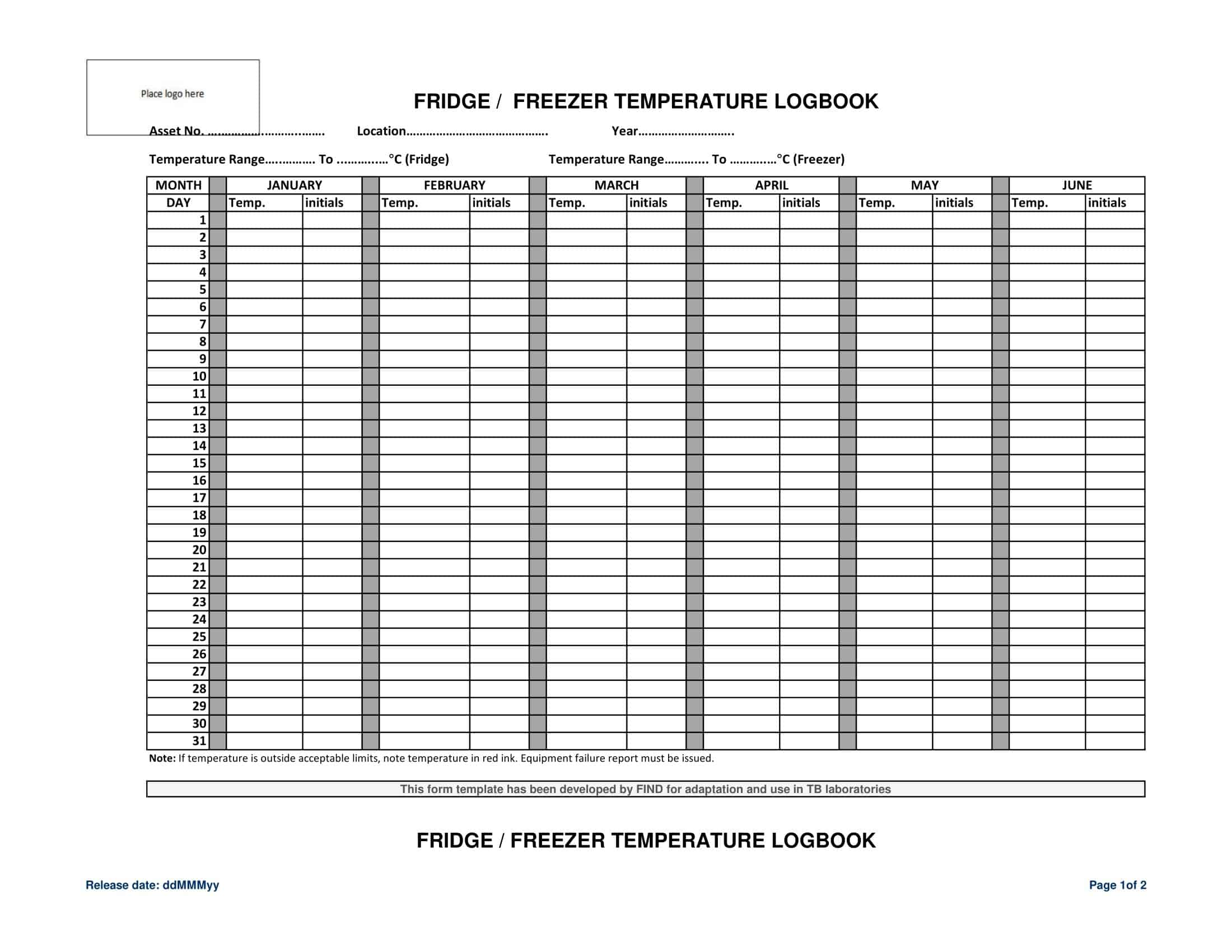

Refrigerator and Freezer Temperature Log Sheets

Refrigerator and freezer temperature log sheets are crucial in various industries, including food service, healthcare, and research laboratories. They track the temperature of refrigeration units, ensuring that the proper conditions are maintained for the storage of sensitive items, such as vaccines, medications, or biological samples.

Cooking and Holding Temperature Log Sheets

These log sheets are used in the food service industry to monitor the temperature of food during cooking and holding processes. They help ensure that food is cooked and held at the right temperature to minimize the risk of bacterial growth and foodborne illnesses.

Transportation Temperature Log Sheets

Transportation temperature log sheets are essential in industries that involve the shipment of temperature-sensitive goods, such as perishable food items, pharmaceuticals, and chemicals. They help monitor and maintain the temperature inside transportation vehicles, ensuring the quality and safety of products during transit.

Equipment and Appliance Temperature Log Sheets

These log sheets are used to track the temperature performance of various appliances and equipment, such as heating, ventilation, and air conditioning (HVAC) systems, ovens, or water heaters. They assist in identifying potential issues and scheduling maintenance to prevent equipment failure or inefficiency.

Ambient Room Temperature Log Sheets

Ambient room temperature log sheets are commonly used in healthcare facilities, research laboratories, and controlled environment facilities to monitor and maintain the room temperature within a specific range. They ensure that the environment is suitable for sensitive processes, patient care, or the storage of temperature-sensitive items.

In summary, temperature log sheets are invaluable tools in various industries for maintaining the quality, safety, and proper functioning of temperature-sensitive items and equipment. By understanding and utilizing the appropriate log sheets, businesses can ensure compliance with regulations and optimize their processes for efficiency and reliability.

When to Use Temperature Log Sheets ?

Temperature log sheets are essential tools for maintaining the quality, safety, and functionality of temperature-sensitive items, equipment, and environments in numerous industries. They help to monitor temperature fluctuations and prompt necessary corrective actions. In this comprehensive guide, we will explore the various situations in which temperature log sheets are needed and how they contribute to maintaining industry standards and best practices.

Food Storage and Preparation

In food service and retail industries, temperature log sheets are crucial for tracking the storage temperature of perishable items such as meats, dairy products, and frozen goods. They help ensure food is stored under optimal conditions, reducing the risk of spoilage and foodborne illnesses. Additionally, during food preparation, these log sheets monitor cooking and holding temperatures, ensuring that food is safe for consumption.

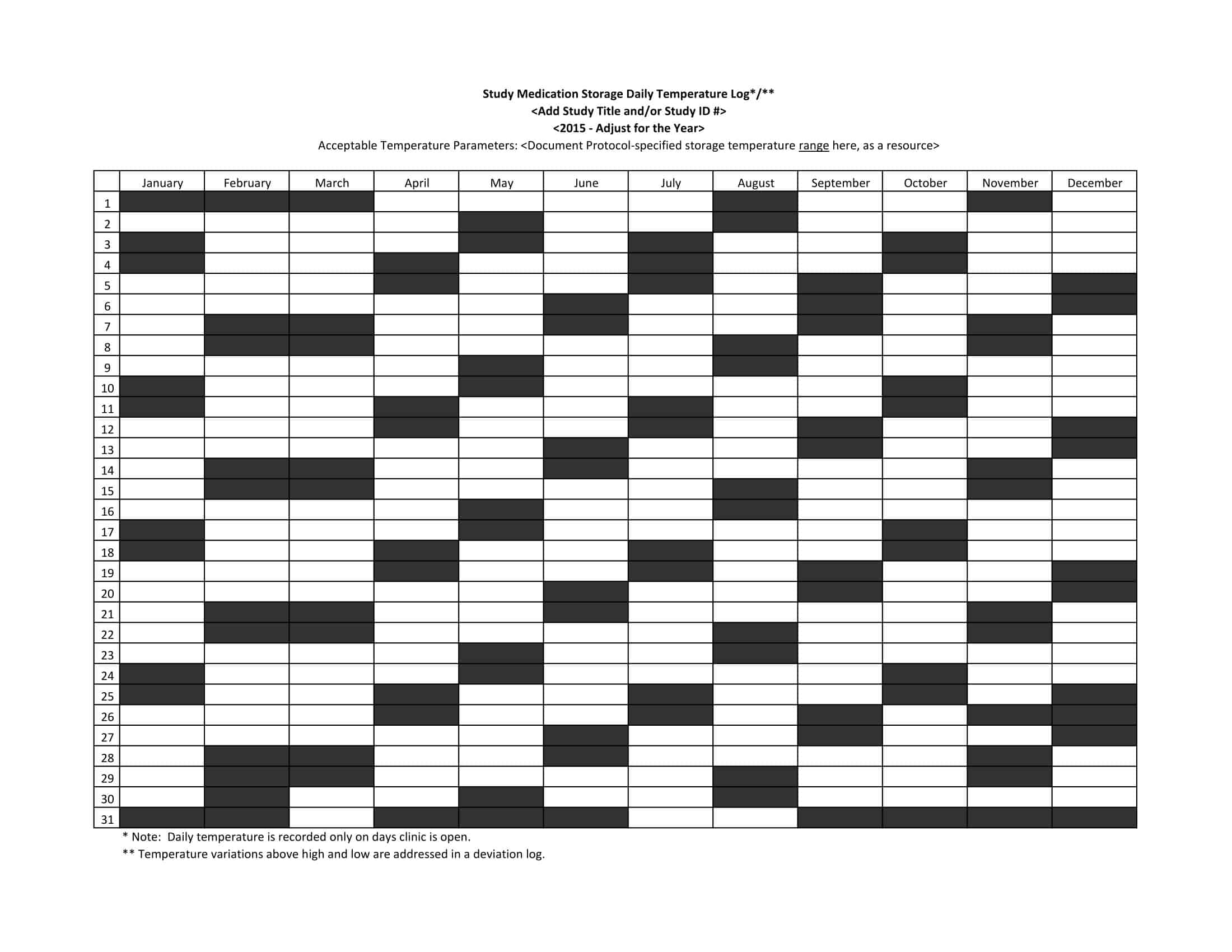

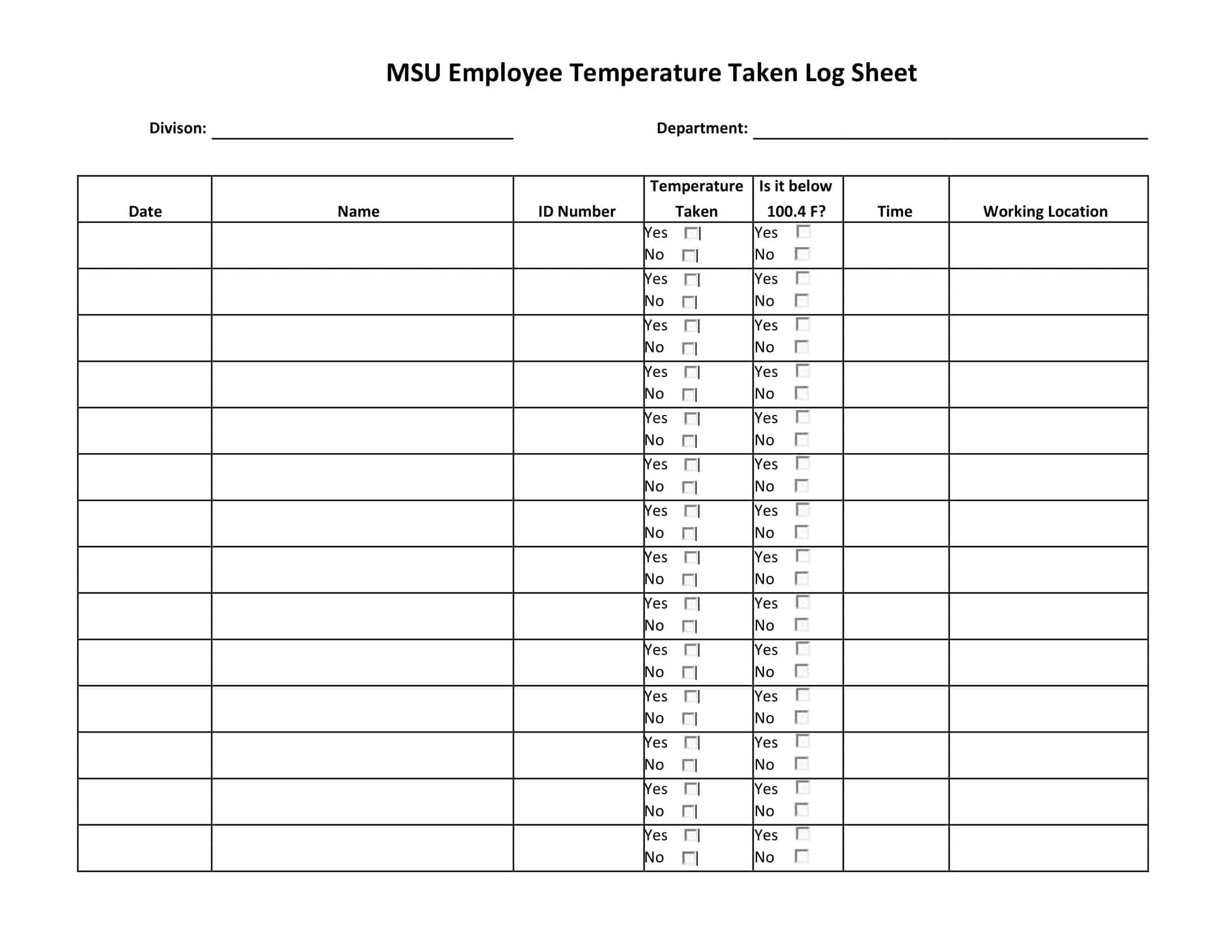

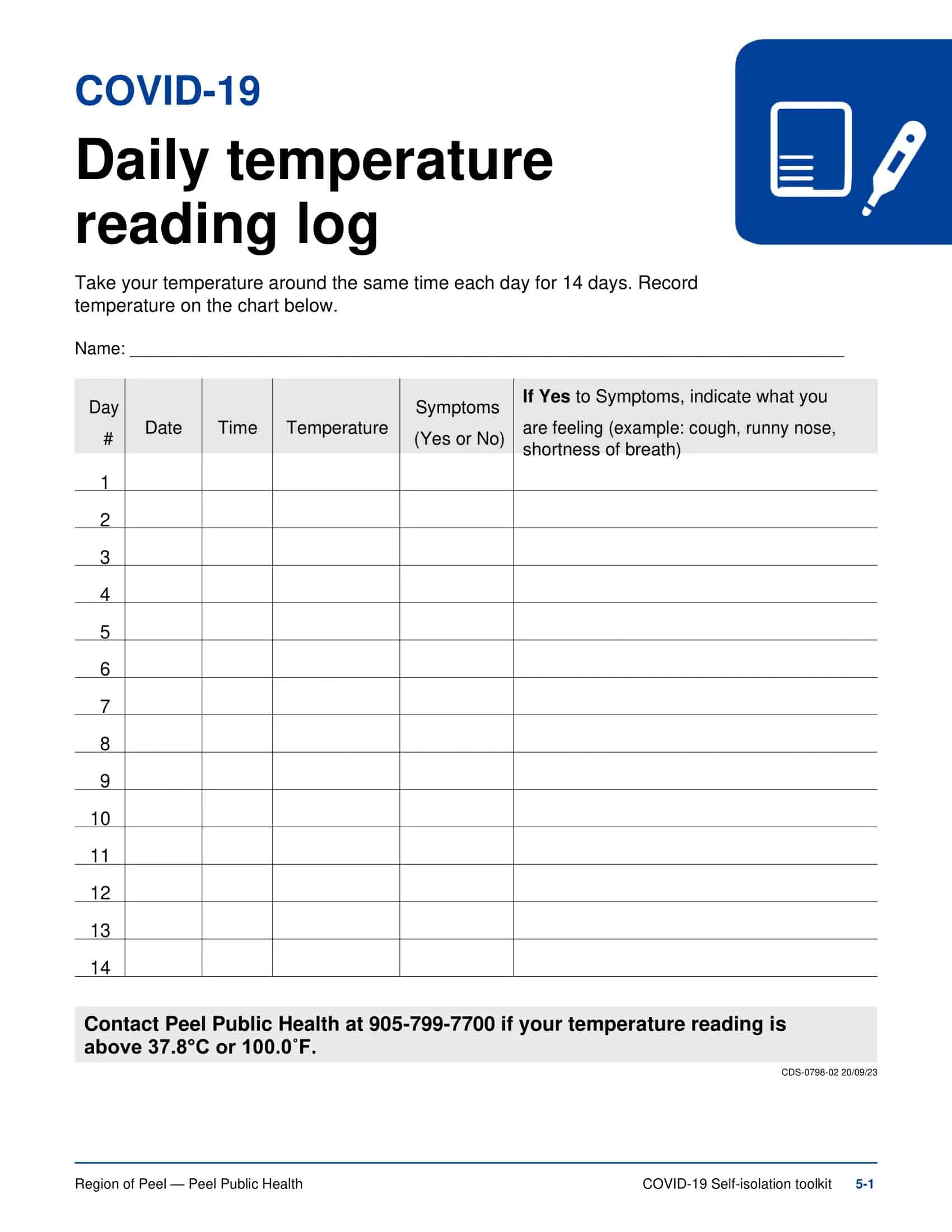

Healthcare and Pharmaceutical Storage

Temperature log sheets are indispensable in healthcare facilities, such as hospitals and clinics, as well as in pharmaceutical storage. They help maintain the proper storage conditions for temperature-sensitive items like vaccines, medications, and biological samples, ensuring their effectiveness and safety.

Research Laboratories

In research laboratories, maintaining accurate temperature conditions is vital for sensitive processes and the storage of various specimens and chemicals. Ambient room temperature log sheets, as well as refrigerator and freezer log sheets, help monitor and maintain the required temperature ranges for these purposes.

Transportation of Temperature-Sensitive Goods

Industries that involve the shipment of temperature-sensitive items, such as perishable foods, pharmaceuticals, and chemicals, rely on transportation temperature log sheets to monitor and maintain the temperature inside transportation vehicles. These log sheets ensure that products are transported under appropriate conditions, preserving their quality and safety.

Equipment and Appliance Monitoring

Temperature log sheets are also used to monitor the temperature performance of various appliances and equipment, including heating, ventilation, and air conditioning (HVAC) systems, ovens, and water heaters. Tracking temperature fluctuations can help identify potential issues, schedule maintenance, and prevent equipment failure or inefficiency.

Controlled Environment Facilities

In controlled environment facilities, such as cleanrooms, data centers, or storage warehouses, maintaining consistent ambient room temperature is crucial for ensuring the quality, safety, and proper functioning of products or processes. Temperature log sheets help monitor and maintain the required temperature ranges in these environments.

How to Create a Temperature Log (A Step-by-Step Guide)

Creating a temperature log is an essential task for ensuring the proper storage and handling of temperature-sensitive items, equipment, and environments across various industries. Here is a step-by-step guide to help you create an effective temperature log:

Step 1: Determine the Purpose and Scope

Before creating your temperature log, identify its purpose and scope. Determine which items, equipment, or environments need temperature monitoring, and consider any specific industry regulations or guidelines that must be followed.

Step 2: Choose the Format

Select an appropriate format for your temperature log. You can create a simple log using pen and paper, a spreadsheet program like Microsoft Excel, or specialized temperature monitoring software. Choose a format that is easy to use and update, and consider the accessibility and storage requirements for your records.

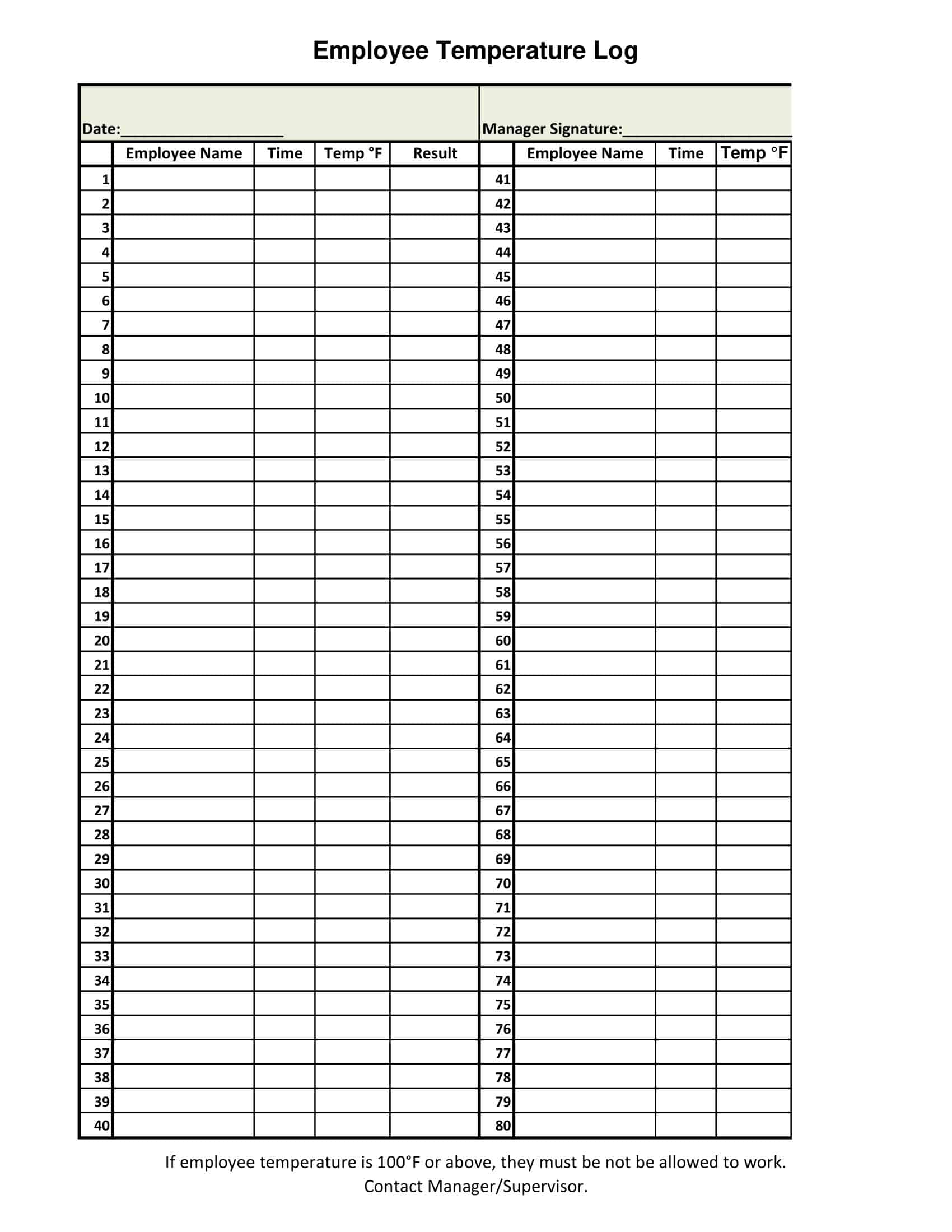

Step 3: Design the Log Layout

Design the layout of your temperature log, including columns and rows for relevant information. Common columns may include the date, time, temperature reading, location or equipment, person responsible for taking the reading, and any comments or actions taken if temperature issues arise. Ensure that the layout is clear and easy to read.

Step 4: Specify the Monitoring Frequency

Determine how often temperature readings should be taken and recorded. The frequency may depend on the specific industry, regulations, or the sensitivity of the items or equipment being monitored. Regular monitoring intervals can help to quickly identify and address temperature fluctuations.

Step 5: Establish Temperature Ranges

Define the acceptable temperature ranges for the items, equipment, or environments being monitored. These ranges may be determined by industry guidelines, manufacturer recommendations, or specific requirements for the items being stored or processes being conducted.

Step 6: Train Staff and Assign Responsibilities

Ensure that staff members responsible for taking temperature readings and maintaining the log are adequately trained in the correct procedures. Assign specific responsibilities for monitoring, recording, and addressing any temperature issues that arise.

Step 7: Implement the Temperature Log

Begin using the temperature log, ensuring that staff members follow the established procedures for taking readings, recording the data, and addressing any temperature fluctuations. Regularly review the log to ensure compliance and identify any patterns or recurring issues that may require further attention.

Step 8: Review and Update the Log

Periodically review and update the temperature log to ensure its effectiveness and relevance. Adjust the monitoring frequency, temperature ranges, or layout as needed to improve the log’s usefulness and adapt to any changes in industry regulations or business operations.

Using a Temperature Log

Temperature logs are critical tools for ensuring the proper storage and handling of temperature-sensitive items, equipment, and environments across various industries. To effectively use a temperature log, follow these steps:

Step 1: Understand the Purpose and Scope

Familiarize yourself with the purpose and scope of the temperature log, including which items, equipment, or environments need temperature monitoring. Ensure you are aware of any specific industry regulations or guidelines that must be followed.

Step 2: Train Staff and Assign Responsibilities

Ensure that staff members responsible for taking temperature readings and maintaining the log are adequately trained in the correct procedures. Assign specific responsibilities for monitoring, recording, and addressing any temperature issues that arise.

Step 3: Follow the Monitoring Frequency

Adhere to the established frequency for taking temperature readings. Consistent monitoring at regular intervals will help to quickly identify and address temperature fluctuations, ensuring the safety and quality of the items or environments being monitored.

Step 4: Take Accurate Temperature Readings

When it’s time to take a temperature reading, use a calibrated and accurate thermometer or temperature monitoring device. Make sure the device is properly placed in the item or environment being monitored, and allow sufficient time for the temperature reading to stabilize.

Step 5: Record the Temperature Data

Record the temperature reading in the log, ensuring that all relevant information is noted, including the date, time, temperature reading, location or equipment, person responsible for taking the reading, and any comments or actions taken if temperature issues arise. Make sure the data is recorded clearly and legibly.

Step 6: Address Temperature Issues

If a temperature reading falls outside the acceptable range, take immediate action to address the issue. This may involve adjusting the temperature of a storage unit, relocating the items to a different location, or notifying a supervisor or maintenance team for further investigation and resolution.

Step 7: Review the Log Regularly

Regularly review the temperature log to ensure compliance with industry standards and identify any patterns or recurring issues that may require further attention. This review process helps maintain the effectiveness of the log and promotes efficient and reliable processes.

Step 8: Maintain the Log and Update as Needed

Keep the temperature log up to date by ensuring that all readings are recorded accurately and consistently. Periodically evaluate the log’s effectiveness and relevance, adjusting the monitoring frequency, temperature ranges, or layout as needed to improve its usefulness and adapt to any changes in industry regulations or business operations.

Key Factors to Keep in Mind When Recording Temperature Readings

When logging temperature readings, it is essential to consider several factors to ensure accurate and useful data collection. Here are some key aspects to keep in mind:

Accuracy of the thermometer or temperature monitoring device: Use a calibrated and accurate thermometer or temperature monitoring device to ensure reliable temperature readings. Regularly check and calibrate the device as necessary.

Proper thermometer or device placement: Ensure the thermometer or monitoring device is placed correctly within the item or environment being monitored. Incorrect placement can result in inaccurate readings, which could affect the quality and safety of temperature-sensitive items.

Consistency in monitoring frequency: Follow the established monitoring frequency for temperature readings to ensure consistent data collection. Consistency will help identify and address temperature fluctuations promptly.

Time of day: Record the time of day when each temperature reading is taken. This information can help identify patterns or trends in temperature fluctuations, allowing you to make adjustments as needed.

Personnel responsible: Clearly identify the person responsible for taking each temperature reading and recording it in the log. This helps to ensure accountability and provides a point of contact if any issues or questions arise.

Temperature ranges: Be aware of the acceptable temperature ranges for the items, equipment, or environments being monitored. Record any readings that fall outside these ranges and take immediate action to address the issue.

Documenting actions taken: If a temperature reading falls outside the acceptable range or indicates a potential issue, document the actions taken to resolve the problem. This information provides a record of how issues are addressed and can help inform future improvements or adjustments.

Regular review and analysis: Periodically review the temperature log to ensure compliance with industry standards and identify patterns or recurring issues that may require further attention. Regular analysis can help improve temperature management practices and promote efficient and reliable processes.

Storage and accessibility: Store the temperature log in a secure and easily accessible location. This ensures that the log is readily available for review, updates, and audits, and helps maintain the integrity and confidentiality of the data.

Compliance with industry regulations: Make sure your temperature logging practices comply with relevant industry regulations and guidelines. Non-compliance can result in fines, penalties, or damage to your business’s reputation.

FAQs

How often should temperature readings be recorded in a temperature log?

The frequency of temperature readings depends on the specific industry, regulations, or the sensitivity of the items or equipment being monitored. Regular monitoring intervals are essential for quickly identifying and addressing temperature fluctuations. The frequency can range from hourly to daily, depending on the situation and requirements.

What information should be included in a temperature log?

A temperature log should typically include the date, time, temperature reading, location or equipment, person responsible for taking the reading, and any comments or actions taken if temperature issues arise. Ensure that the information is recorded clearly and legibly.

What types of thermometers or temperature monitoring devices can be used for temperature logs?

Various thermometers and temperature monitoring devices can be used for temperature logs, including digital thermometers, infrared thermometers, temperature data loggers, and wireless temperature sensors. The choice depends on the specific application, accuracy requirements, and budget.

How can I ensure the accuracy of temperature readings?

To ensure accurate temperature readings, use a calibrated and accurate thermometer or temperature monitoring device. Regularly check and calibrate the device as necessary, and make sure it is placed correctly within the item or environment being monitored.

How do I store and maintain temperature logs?

Store temperature logs in a secure and easily accessible location to ensure their availability for review, updates, and audits. Maintain the logs by ensuring that all readings are recorded accurately and consistently, and periodically evaluate their effectiveness and relevance, adjusting as needed.

Are temperature logs required by law?

In some industries, such as food service, healthcare, and pharmaceuticals, temperature logs may be required by law or regulations to ensure the quality, safety, and proper storage of temperature-sensitive items. It is essential to comply with the relevant industry regulations and guidelines for temperature logging.

Can I use digital tools or software for temperature logging?

Yes, digital tools and software can be used for temperature logging, including spreadsheets like Microsoft Excel or specialized temperature monitoring software. These tools can offer advantages such as automated data collection, real-time monitoring, and easier analysis and reporting. Choose a solution that fits your needs and requirements.

![Free Printable Roommate Agreement Templates [Word, PDF] 1 Roommate Agreement](https://www.typecalendar.com/wp-content/uploads/2023/06/Roommate-Agreement-150x150.jpg)

![Free Printable Credit Card Authorization Form Templates [PDF, Word, Excel] 2 Credit Card Authorization Form](https://www.typecalendar.com/wp-content/uploads/2023/06/Credit-Card-Authorization-Form-150x150.jpg)

![Free Printable Stock Ledger Templates [Excel,PDF, Word] 3 Stock Ledger](https://www.typecalendar.com/wp-content/uploads/2023/08/Stock-Ledger-150x150.jpg)