Properly maintained panel schedules are crucial for ensuring the safety of service personnel, contractors, and equipment. In an emergency, accurate and up-to-date panel schedules can save valuable time and ensure the safety of those working on or near the equipment.

Not only do they assist in determining which equipment is powered by which breaker, but they also provide a reference point for locking and tagging out for safety. Additionally, appropriate labeling standards are essential for identifying the correct apparatus to be de-powered, particularly in situations where there are multiple breakers controlling identical machinery or when personnel are not familiar with the infrastructure.

Table of Contents

What is a panelboard schedule?

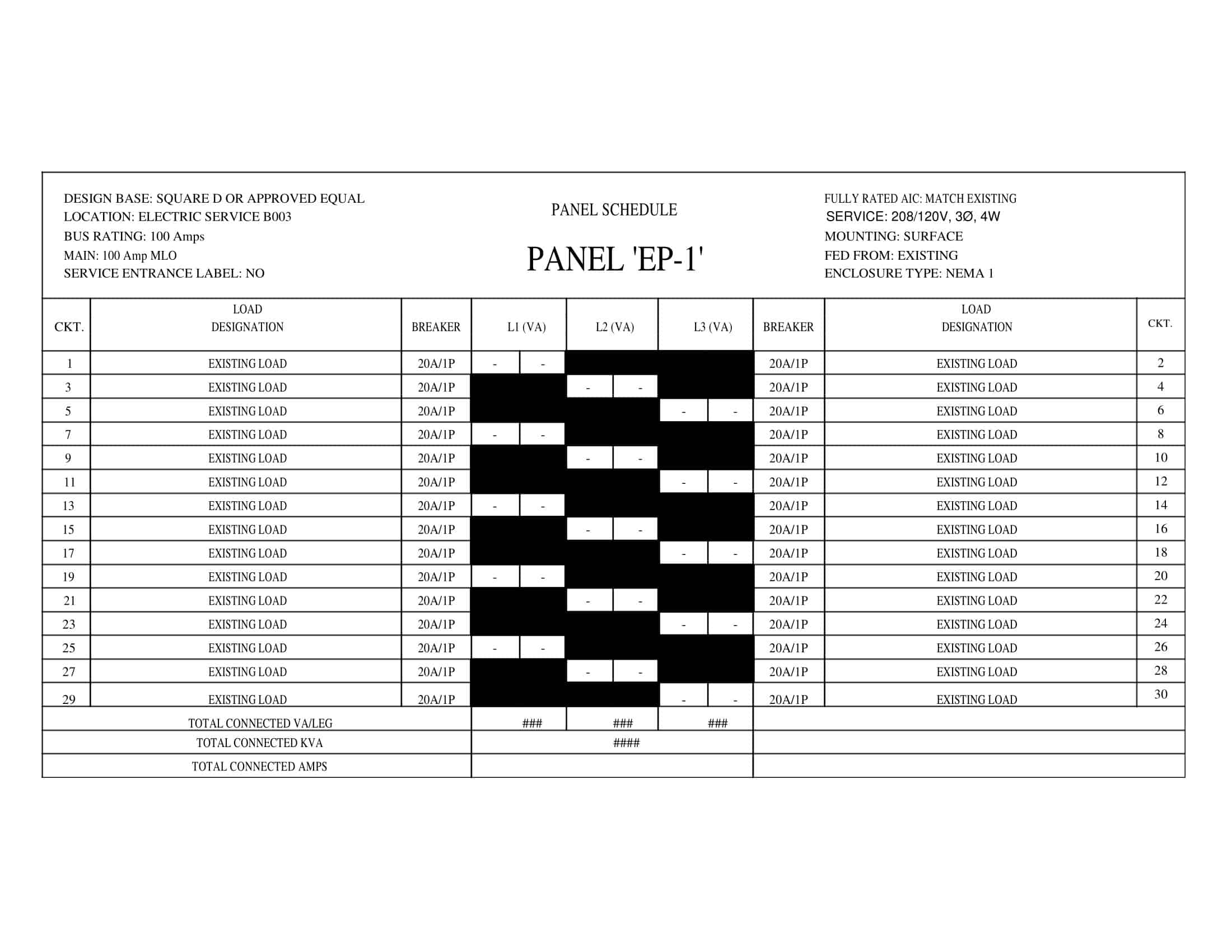

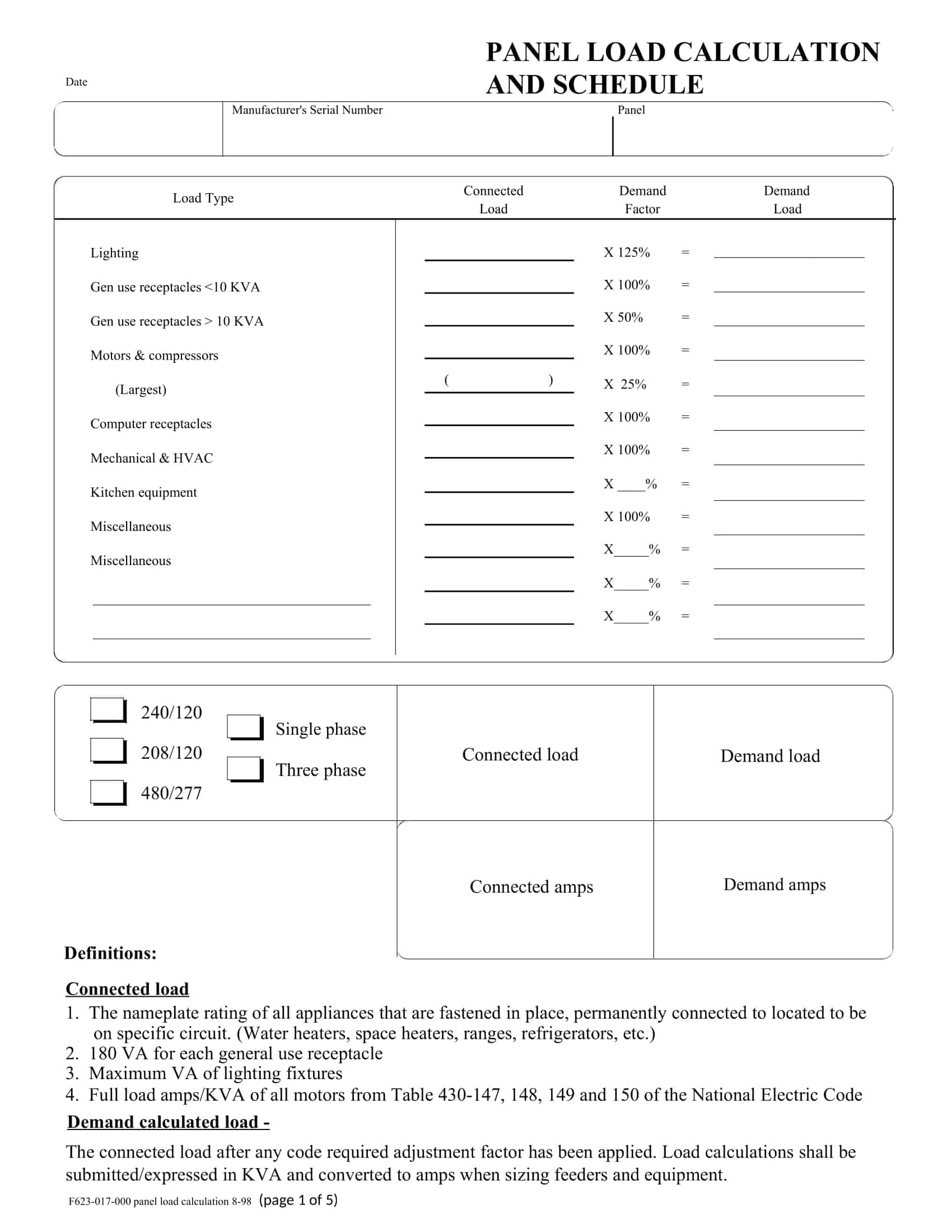

A panelboard schedule is a document that provides detailed information about the electrical panelboard and its components. It typically includes information such as the panelboard’s location, the number and type of circuits, the amperage rating of each circuit, and the load on each circuit. It also includes information about the breakers or fuses that protect each circuit, as well as their ratings and trip settings.

The panel schedule is an important safety tool that provides a clear and concise reference of the electrical distribution system, it is used to identify the electrical power source for a specific equipment, to properly maintain the system, to troubleshoot issues, and to plan for future upgrades and maintenance. This document is usually found in the main electrical room or near the panelboard and it is updated regularly to reflect any changes in the electrical distribution system.

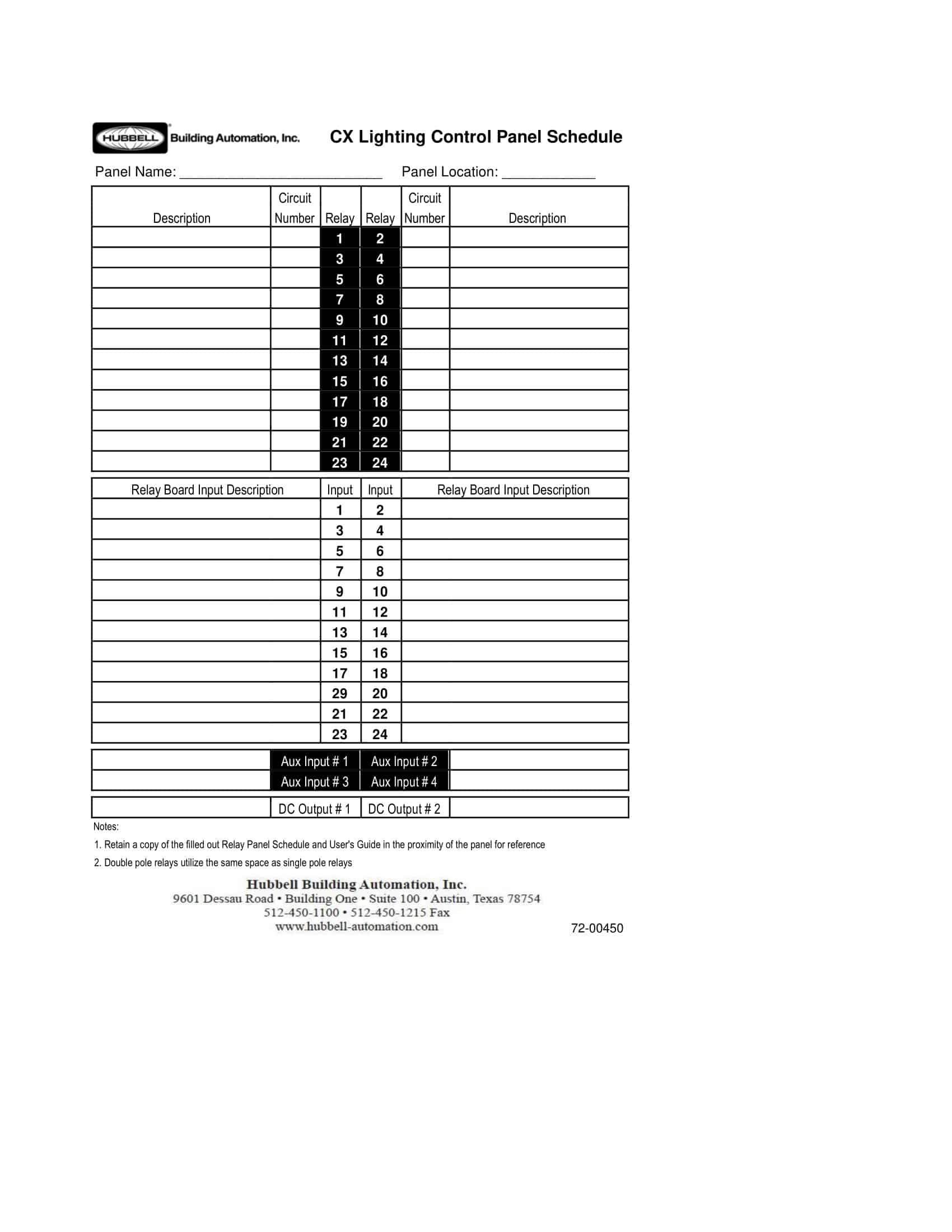

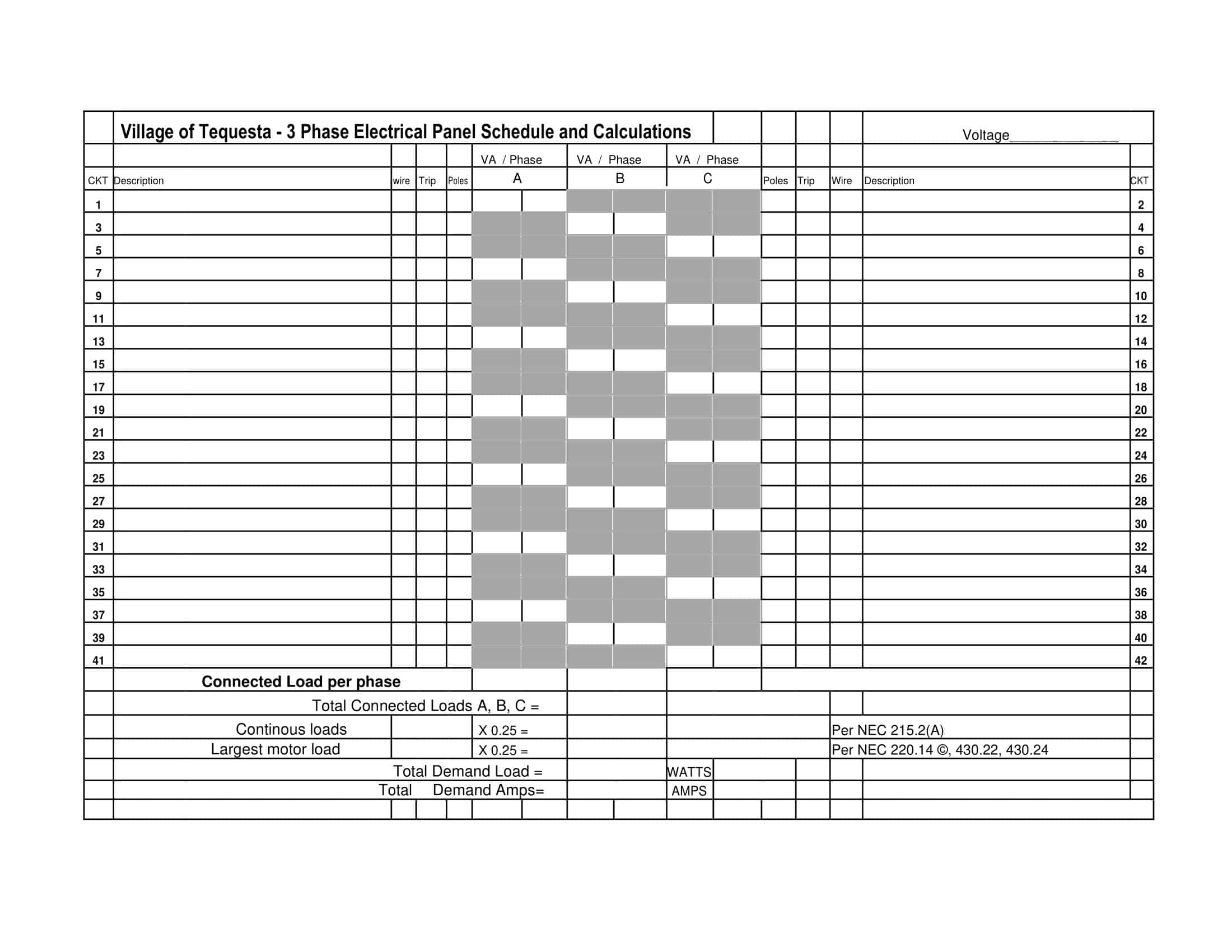

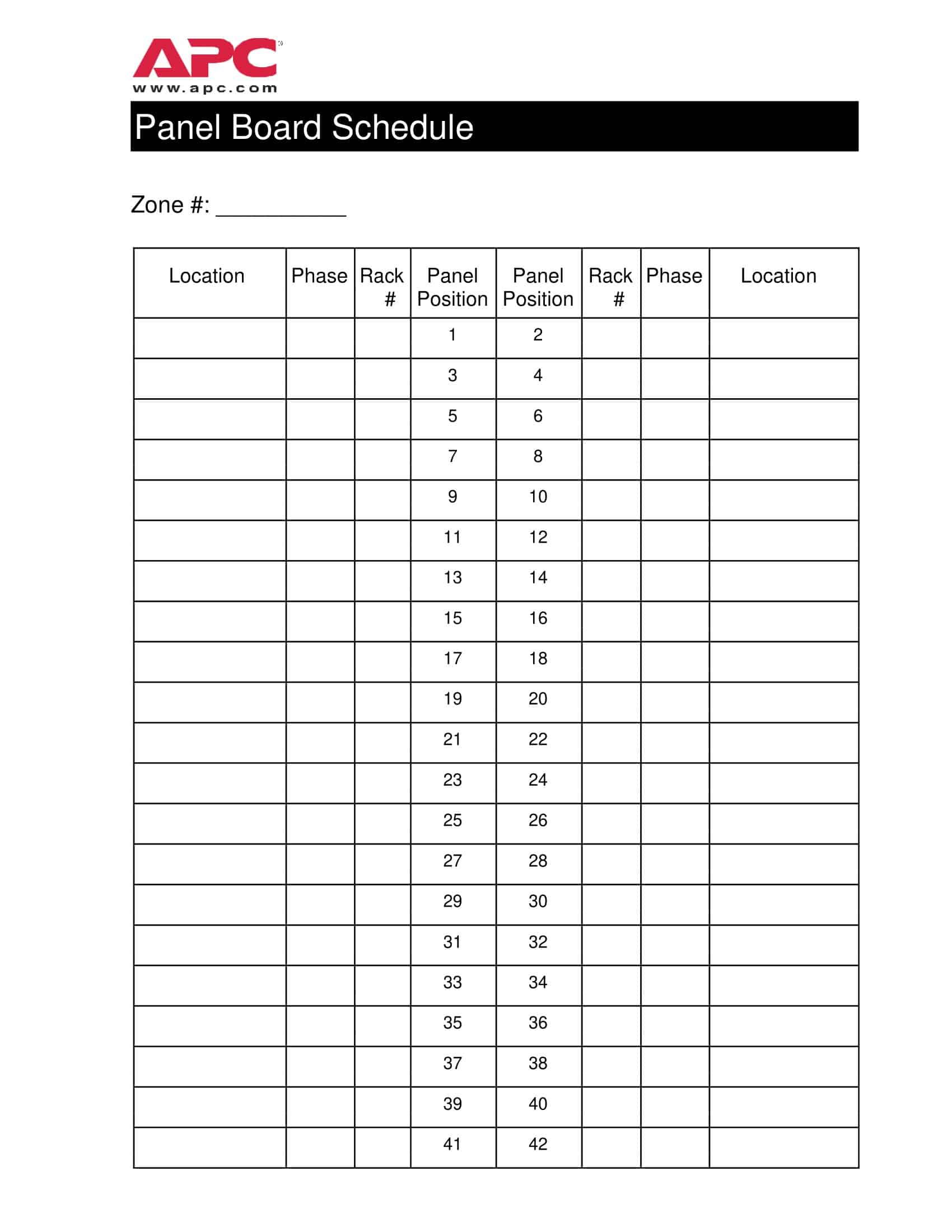

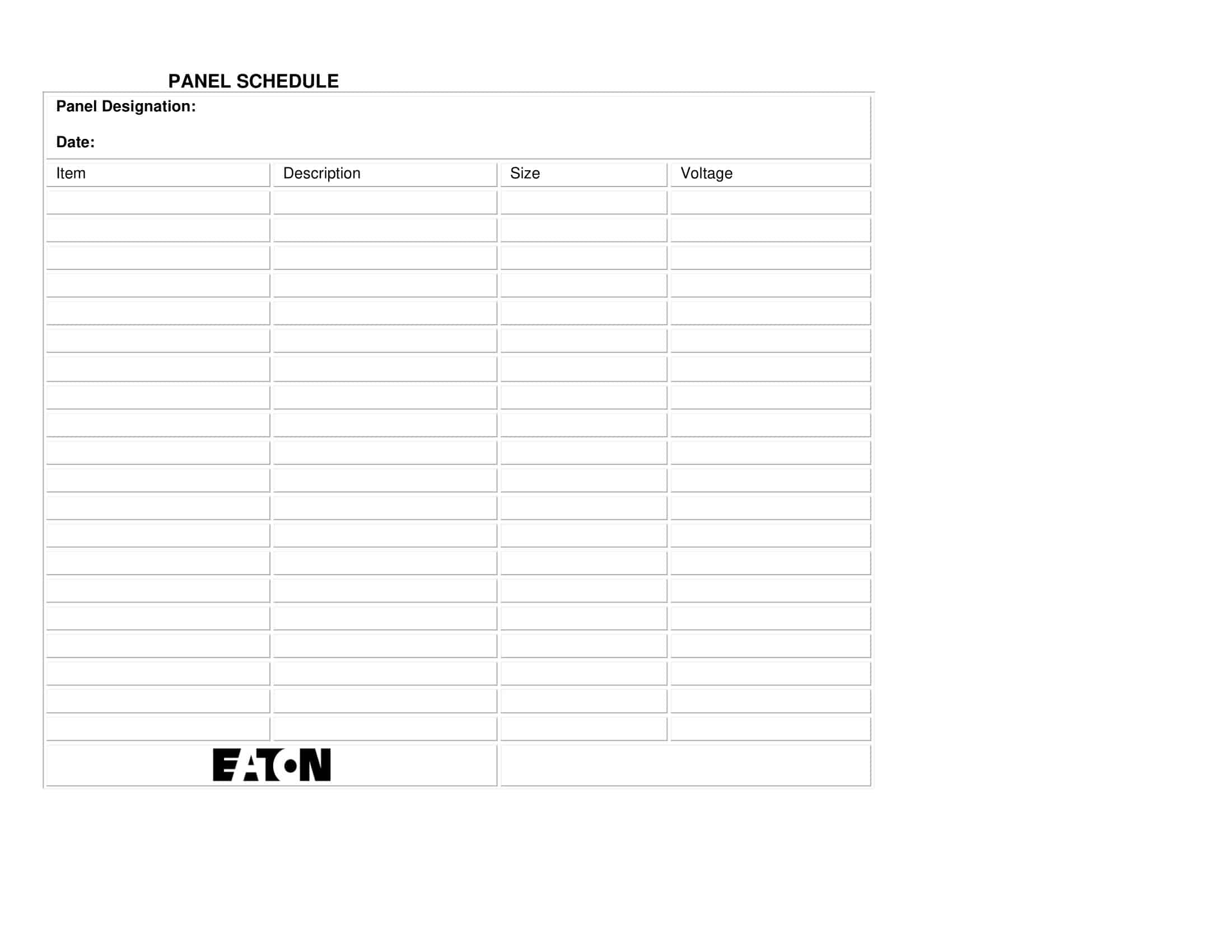

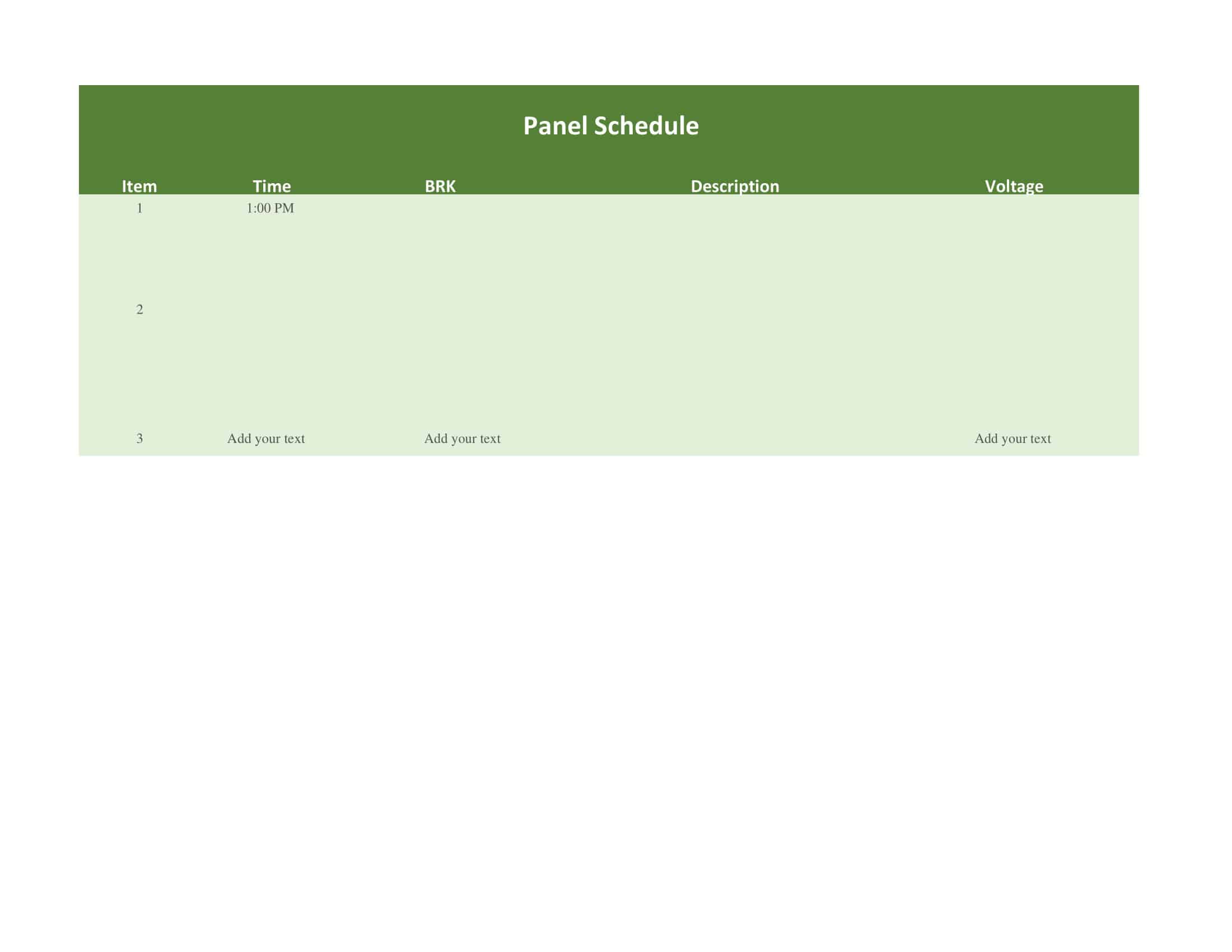

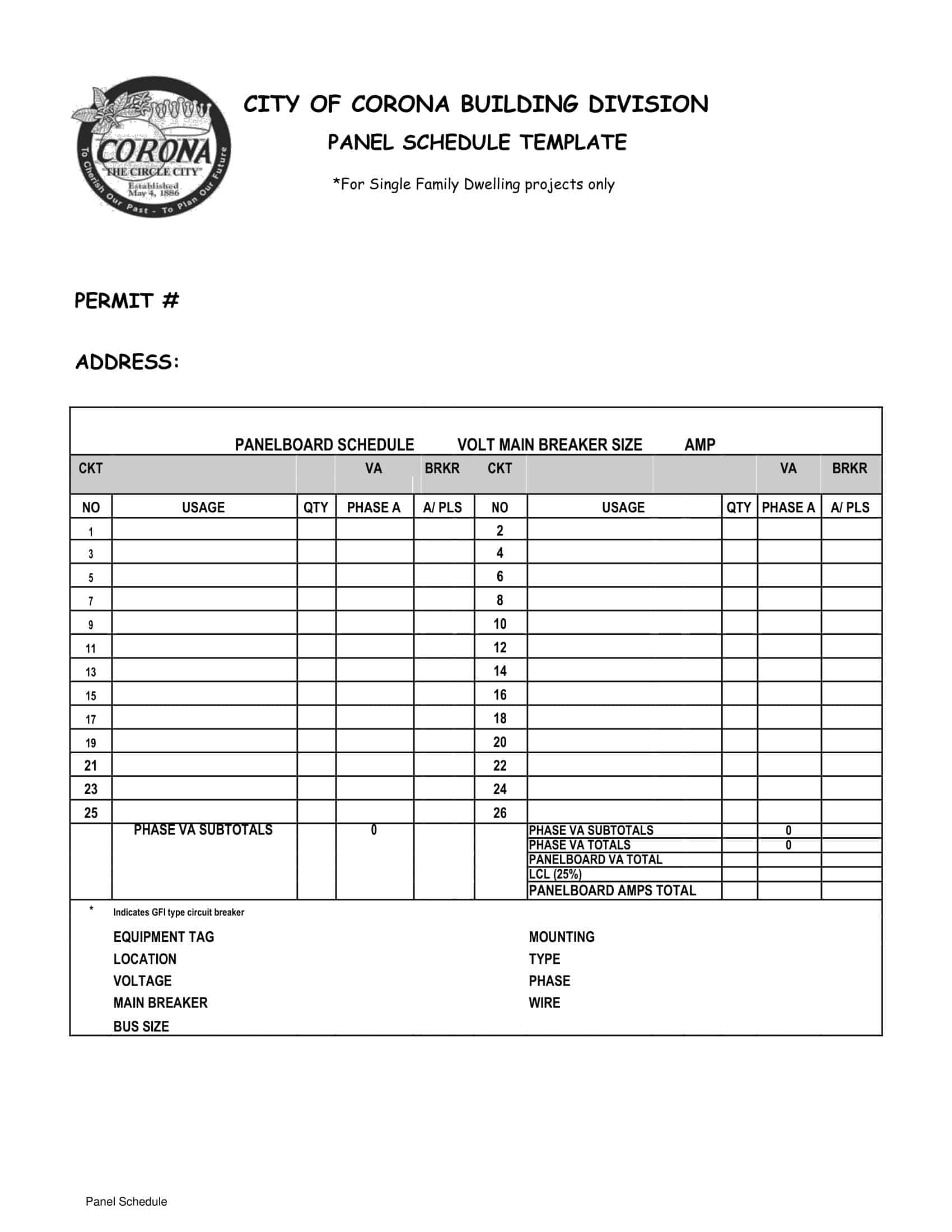

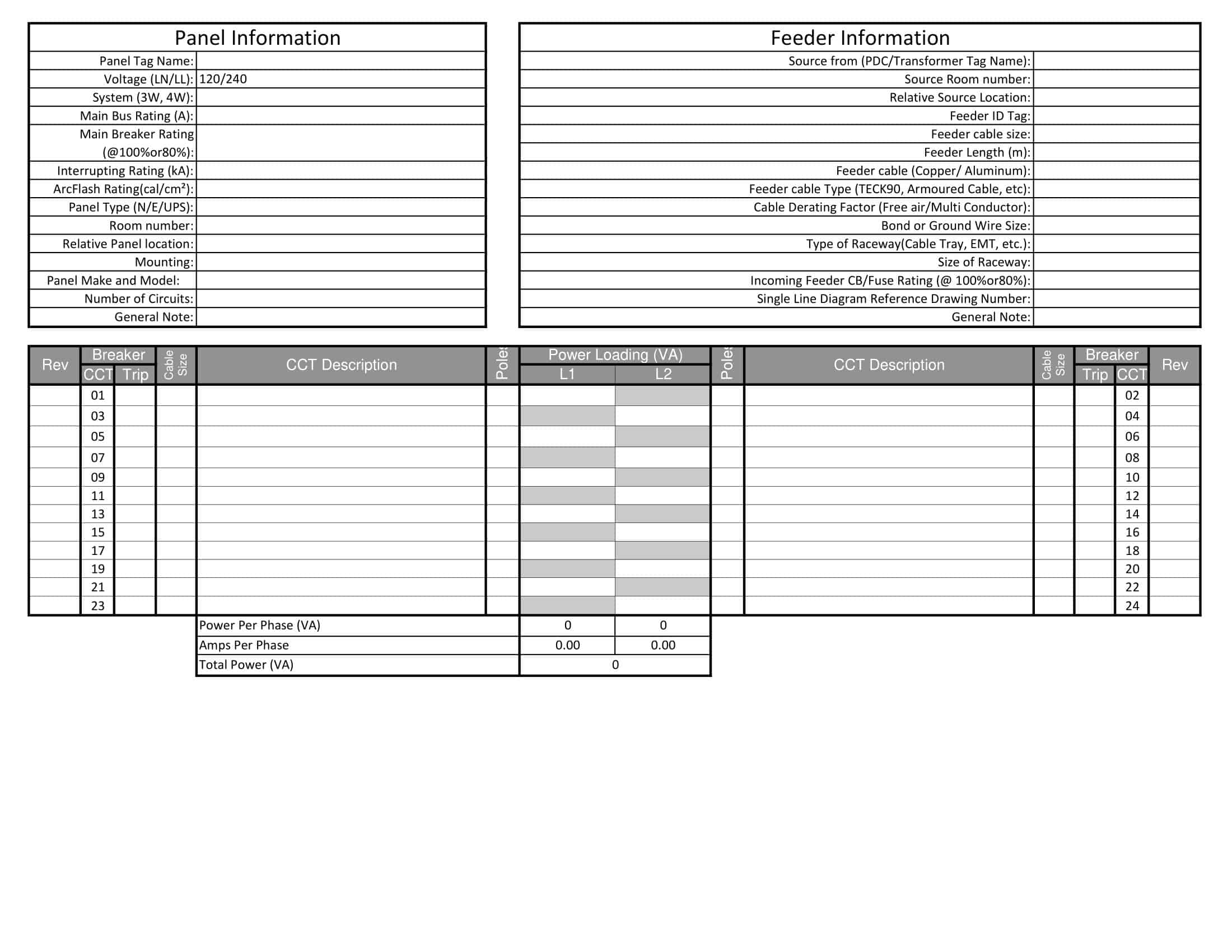

Panel Schedule Templates

Panel Schedule Templates are valuable tools used in electrical engineering and construction projects to document and organize information about electrical panels and their corresponding circuits. These templates provide a structured format for recording essential details about the electrical distribution system within a building or facility. Panel Schedule Templates assist electrical engineers, electricians, or project managers in designing, documenting, and maintaining electrical systems effectively.

Panel Schedule Templates are crucial for organizing and managing electrical systems in residential, commercial, or industrial settings. By utilizing these templates, electrical professionals can maintain accurate records of panel configurations, circuit details, and load information.

Panel schedules help ensure compliance with electrical codes and regulations, facilitate troubleshooting and maintenance activities, and support effective communication among project stakeholders. Whether used in the design phase, during construction, or for ongoing maintenance purposes, Panel Schedule Templates provide a standardized and efficient approach to documenting and managing electrical panels and circuits.

What information a panel board schedule show?

A panelboard schedule typically shows the following information:

Panelboard location: The location of the panelboard, including the room or area where it is located.

Circuit information: The number and type of circuits in the panelboard, as well as their amperage rating and load.

Breaker or fuse information: The type, rating, and trip settings of the breakers or fuses that protect each circuit.

Circuit identification: Each circuit is identified by a unique number or label, which corresponds to the equipment or load it serves.

Voltage and Phase: Voltage and phase of the electrical power source for each circuit.

Maintenance and inspection: A record of the maintenance, inspection and testing of the panelboard and its components.

Safety information: Information on how to safely de-energize and lock out the panelboard for maintenance or repair.

Additional notes: Any additional notes or information that may be relevant to the safe and efficient operation of the panelboard.

Importance of panel schedules

Panel schedules are an important tool for ensuring the safe and efficient operation of an electrical system. The following are some of the key benefits of panel schedules:

Safety

Panel schedules provide critical information for safely de-energizing and locking out a panelboard for maintenance or repair. This helps to prevent accidents and injuries to personnel working on the electrical system.

Maintenance

Panel schedules provide detailed information about the electrical panelboard and its components, which is essential for proper maintenance and troubleshooting. This helps to extend the life of the equipment and reduce the likelihood of failures and downtime.

Efficiency

Panel schedules provide a clear and concise reference of the electrical distribution system, which helps to prevent errors and improves the efficiency of the electrical system.

Compliance

Panel schedules are often required by codes and regulations as a way to document and maintain the electrical system, having a current and accurate panel schedule is important for compliance with local and national electrical codes.

Planning

Panel schedules provide valuable information for planning future upgrades and expansions of the electrical system. It helps to identify any limitations or potential issues that may need to be addressed.

Training

Panel schedules provide a useful reference for training new personnel or contractors on the electrical system, allowing them to quickly understand the layout and operation of the equipment.

Troubleshooting

Panel schedules provide detailed information about the electrical panelboard and its components, which is essential for proper troubleshooting. This helps to quickly identify and isolate the source of any problems or issues that may occur in the electrical system, reducing downtime and increasing efficiency.

Updating

Panel schedules should be updated regularly to reflect any changes in the electrical distribution system, such as new equipment, changes in load, or modifications to the panelboard. This helps to ensure that the information on the schedule is accurate and up-to-date, which is critical for safety, maintenance, and compliance.

Auditing

Panel schedules can be used as an effective tool for auditing the electrical system, allowing for identification of any potential hazards or issues that need to be addressed.

How to make a panel schedule?

A panel schedule is a document that lists all of the electrical panels, circuits, and equipment in a building or facility, and shows how they are connected to one another. Here are the steps to create a panel schedule:

Gather all necessary information

This includes the building plans, electrical drawings, and any other relevant documents. Make sure that you have the most current versions of these documents.

Create a template

Create a template for the panel schedule that includes all of the necessary information fields, such as panel location, circuit number, and load calculations.

Fill in the template

Using the information from the building plans and electrical drawings, fill in the template with the appropriate information for each panel and circuit.

Label the panels and circuits

Label each panel and circuit clearly and legibly, using a label maker or a pen. Make sure that the labels match the information in the template.

Add load calculations

For each circuit, calculate the load (in amps) based on the electrical specifications of the equipment connected to that circuit.

Organize the schedule

Organize the schedule in a logical and easy-to-read format, such as by panel location or circuit number.

Review and edit

Review the schedule for accuracy and completeness. Make any necessary corrections or additions.

Finalize the schedule

Once you have reviewed and edited the schedule, print it out or save it in a digital format. Make sure that the final version of the schedule is clear and legible.

Distribute the schedule

Distribute the schedule to all relevant parties, such as the building owner, the electrical contractor, and the local building department.

Types of electrical panel schedule

There are several types of electrical panel schedules that are commonly used in different types of projects. Some of the most common types include:

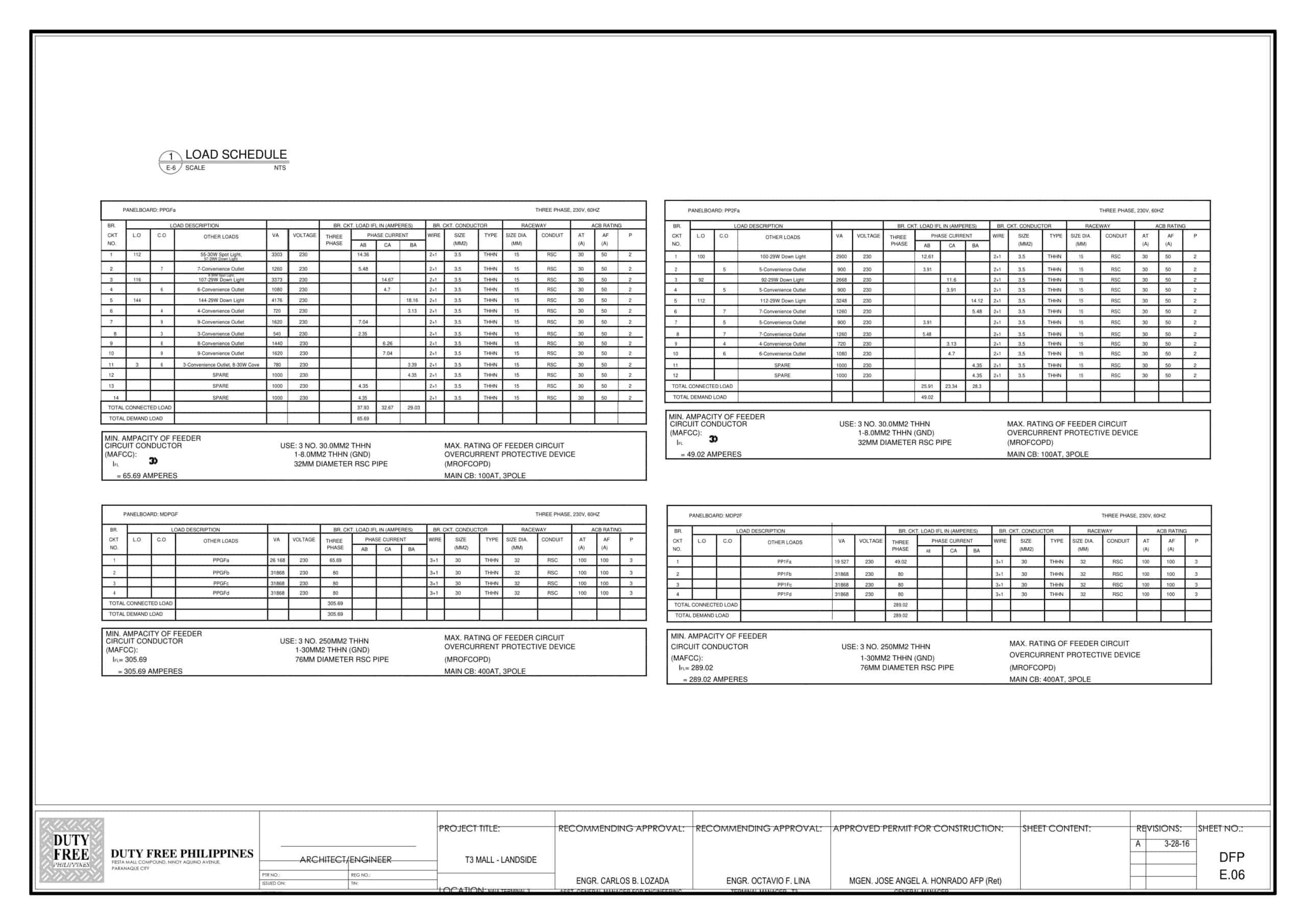

Branch Panel Schedule: This type of schedule lists all of the branch circuits in a building or facility and shows how they are connected to the main electrical panel. It includes information such as the circuit number, load calculations, and the location of each circuit.

Data Panel Schedule: This type of schedule is used in facilities that have a large number of data and communication lines. It shows the location and type of data cabling, as well as the equipment that it connects to.

Switchboard Panel Schedule: This type of schedule is used in large commercial or industrial facilities that have multiple switchboards. It shows the location and type of switchgear, as well as the circuits that are connected to each switchboard.

Lighting Panel Schedule: This type of schedule shows the location and type of lighting fixtures in a building or facility, as well as the circuits that power them. It also includes information about the type of lamp, the number of lamps, and the total power consumption of each fixture.

Power Panel Schedule: This type of schedule is used in facilities that have large power loads, such as industrial plants or data centers. It shows the location and type of power equipment, as well as the circuits that are connected to each piece of equipment.

Important terms in a Panel Schedule

Absorbed Power: This refers to the amount of power (measured in watts) that is consumed by a piece of equipment or a circuit. It is calculated by multiplying the voltage and current of the circuit.

Efficiency: This refers to the ratio of the output power of a piece of equipment or a circuit to the input power. It is usually expressed as a percentage and is a measure of how effectively the equipment or circuit is using the power it is consuming.

Non-Process Loads: These are loads that are not directly related to the production process of a facility, such as lighting and HVAC systems. They are considered to be separate from process loads, which are directly related to production.

Process Loads: These are loads that are directly related to the production process of a facility, such as machinery and equipment.

Power Factor: This refers to the ratio of the actual power (measured in watts) consumed by a piece of equipment or a circuit to the apparent power (measured in volt-amperes). It is a measure of how effectively the equipment or circuit is using the power it is consuming.

These terms are relevant to the panel schedule because they are used to calculate the load calculations and to determine the power needs of the equipment and circuits in a building or facility. It is important to include this information in the panel schedule so that the electrician can identify potential issues with power usage and take steps to address them.

FAQs

What is the purpose of a panel schedule?

The purpose of a panel schedule is to provide a detailed diagram of the electrical panel, including the location and type of circuits, the load calculations, and the equipment that is connected to each circuit. It is used to help electricians troubleshoot and maintain the electrical system and to ensure compliance with local and national regulations.

Who uses panel schedules?

Panel schedules are used by electricians, electrical engineers, building owners, and local building departments. Electricians use them to identify the location and type of circuits, while engineers use them to design and assess the electrical system. Building owners use them to maintain the electrical system and comply with regulations, and building departments use them to ensure compliance with local and national codes.

How are panel schedules created?

Panel schedules are created by gathering all necessary information, such as building plans and electrical drawings. A template is then created and filled in with the appropriate information for each panel and circuit. The schedule is then reviewed, edited, and finalized before being distributed to all relevant parties.

Are there different types of panel schedules?

Yes, there are different types of panel schedules, such as branch panel schedules, data panel schedules, switchboard panel schedules, lighting panel schedules, and power panel schedules. The type of schedule used will depend on the specific requirements of the project and the jurisdiction in which it is located.

How often should panel schedules be updated?

Panel schedules should be updated whenever changes are made to the electrical system, such as the addition of new panels or circuits. This will ensure that the schedule remains accurate and useful for troubleshooting and maintenance purposes.

Why is it important to label the panels and circuits correctly?

Labeling the panels and circuits correctly is important because it allows electricians to quickly and easily identify the location and type of circuits. It also helps to ensure compliance with local and national regulations and to improve safety by identifying the power source of the equipment.

Is it necessary to use a specific software or program to create a panel schedule?

No, it is not necessary to use a specific software or program to create a panel schedule. It can be created using standard office software such as Microsoft Excel or Word, and can also be hand-drawn if desired. However, using specialized software like AutoCAD for creating panel schedules can make it easier to create detailed and accurate diagrams.

Can a panel schedule be used for both new and existing buildings?

Yes, a panel schedule can be used for both new and existing buildings. For new buildings, it is used to design and plan the electrical system, while for existing buildings, it is used to document the existing system and make updates and improvements.

Can a panel schedule be used for both residential and commercial buildings?

Yes, a panel schedule can be used for both residential and commercial buildings. However, the information and level of detail included in the schedule may vary depending on the type and size of the building.

How is a panel schedule different from an equipment schedule?

A panel schedule provides detailed information about the electrical panel and the circuits connected to it, while an equipment schedule provides detailed information about the specific equipment and its power requirements. A panel schedule helps electricians to identify which machine needs power, while equipment schedule guides on the type of wiring and power are required for certain equipment in terms of ampacity, volts, or phase.

![%100 Free Hoodie Templates [Printable] +PDF 1 Hoodie Template](https://www.typecalendar.com/wp-content/uploads/2023/05/Hoodie-Template-1-150x150.jpg)

![Free Printable Food Diary Templates [Word, Excel, PDF] 2 Food Diary](https://www.typecalendar.com/wp-content/uploads/2023/05/Food-Diary-1-150x150.jpg 150w, https://www.typecalendar.com/wp-content/uploads/2023/05/Food-Diary-1-1200x1200.jpg 1200w)

![Free Printable Roommate Agreement Templates [Word, PDF] 3 Roommate Agreement](https://www.typecalendar.com/wp-content/uploads/2023/06/Roommate-Agreement-150x150.jpg)